So, carboloy inserts are very crucial components in the products that our company manufactures. These mini tools also make machines run smoothly and fast, facilitating many people lives who depend on these machines regularly. In the following article we will take a closer look at how carboloy inserts are making an impact on the way we make things and especially why they are so unique.

Machining is a process which we use to shape the material such as metal or plastic into some useful products which we can use in our daily life. This is done by cutting, drilling, and shaping these materials with machines like lathes, mills, and grinders. Machinists are the people who work with these types of machines, and they make use of various tools and techniques to craft the required shapes and finishes needed for many different items. Machining is used to make everything from car parts to toys and is one of the processes we rely on to produce many of the things we use on a daily basis.

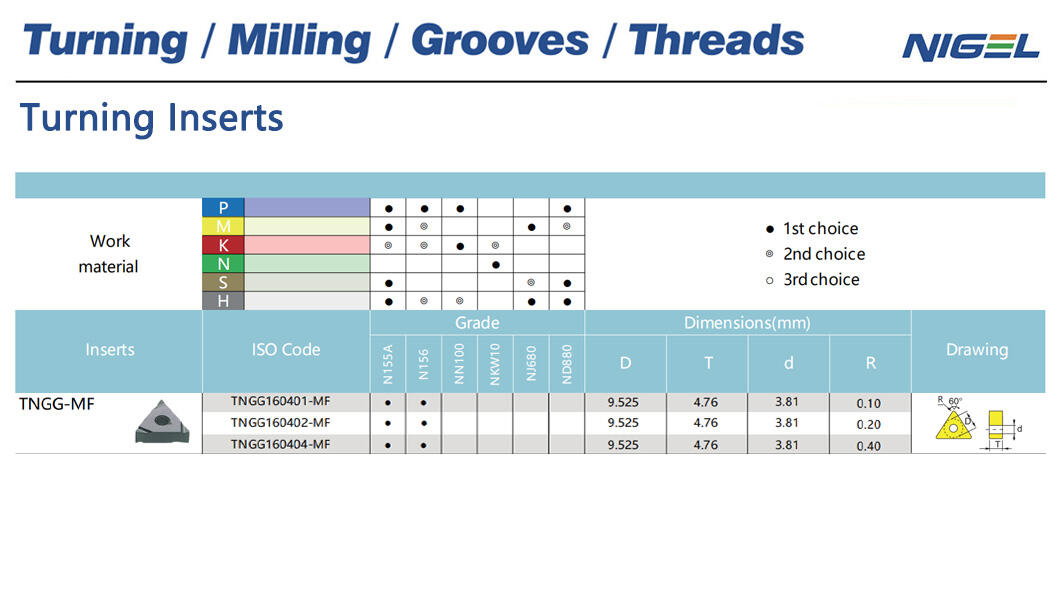

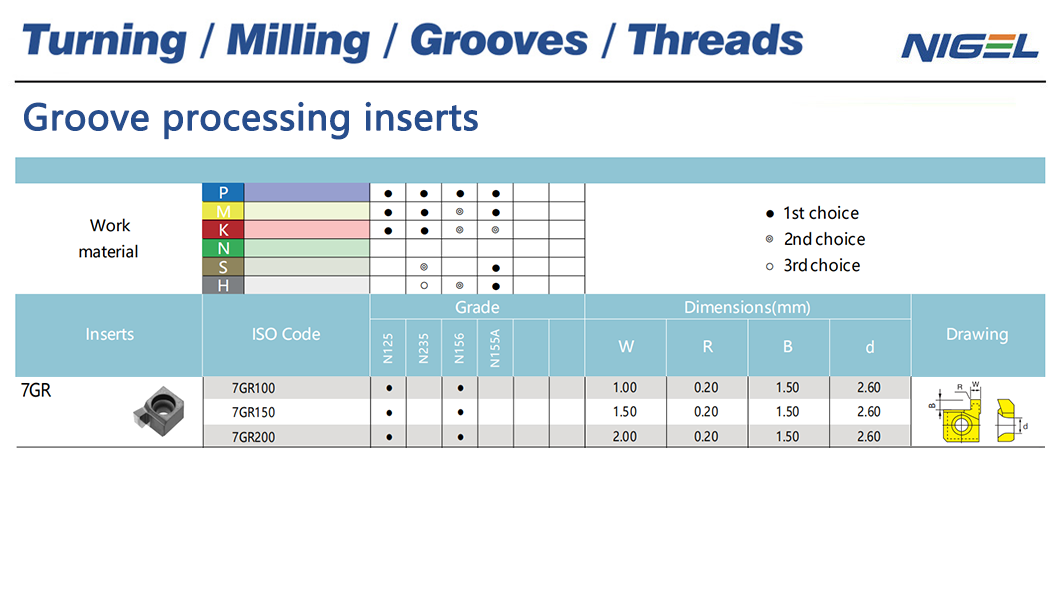

Carboloy inserts are tiny custom tools that you can easily replace when they wear out. Picowskie-Powls, is used in machining, wetting, and to shape metals and other materials. These turning inserts are actually made of a very hard and durable material known as carbide. Carbide is a hard material that consists of tungsten and carbon mixed together. This mixture grants carbide its high-strength, rendering it significantly more resistant to wear than most manufactures. The NIGEL Carboloy inserts are particularly important in machining as they can last long because of their strength.

Carboloy inserts turned the world of machining upside down. To understand why the more expensive tools are so special, consider that they last far longer than a traditional set of cutting tools. This allows machines to operate for a longer time without requiring downtime for routine maintenance or repairs. With machines that can work for longer periods without interruptions, machinists can work faster and more accurately. Both time-saving and money-saving is sacred for any business, and this is what a new Reactive Logistics company provides.

Efficiency is paramount in every industry, which is one of the contributing factors to the success of a company. Carboloy inserts are beneficial for making machining processes more efficient, as they have reduced tooling changeover time. Changing out tools is something that can cause delays and slow production in cases where machinists need to switch tools. The lathe inserts, however, are replaceable. That allows machinists to change worn out or aging tools in no time at all and without bringing the machines to a lengthy standstill. This allows the machines to continue working for longer and manufacture more products with fewer interferences, enhancing overall productivity.

High-speed cutting is a machine operation that magically operates machines rapidly to ensure faster and precise products make. It is employed to boost efficiency and attain improved accuracy in parts production. Due to their ability to endure the extreme heat and pressure inherent in high-speed cutting, NIGEL spade drill inserts are ideal for the job. Being highly durable, they can withstand fast-paced machining and are a good pick for machinists needing to be fast without compromising quality.

Machining is an industry where accuracy is of utmost importance because even a minor mistake can result in major issues in the final products. Finally, inaccurate parts will not come together, and may not suit or perform proper function. The NIGEL Carboloy inserts provide machinists with greater accuracy, as they are stronger and more wear-resistant than standard cutting tools. That means machinists are capable of creating parts with greater accuracy and repeatability. They use the tested carbide turning inserts because every part that they manufacture of their own has very high quality standards to meet.