In this lesson, we will discuss carbide inserts and the role they can play in your projects. Carbide inserts are small, yet highly durable blade which is used in most cutter machine. These inserts—tungsten carbide. It is made out of tungsten carbide, which is a high heat durable metal. It simply means when you are using carbide inserts you can rest assured that they shall lend themselves effectively for many cutting jobs to come.

Carbide inserts cut through materials like metal and alloys. Due to the fact that threading inserts are much harder than other cutting tools, they can perform heavy cutting jobs without breaking or dulling. This attribute is particularly critical in factories and making settings, where assembling things accurately and precisely is vital. Make sure your work quality is good with reliable tools.

Carbide inserts are made up of tungsten carbide, a tool material that consists of the two materials tungsten and carbon mixed together. This unique mixture makes tungsten carbide quite hard and prone to resist the wear and tear from cutting. Tungsten carbide also resists corroding and heat. This is a very large issue for cutting jobs where there may be either high temperature or chemicals, as it helps keep the tools running strong.

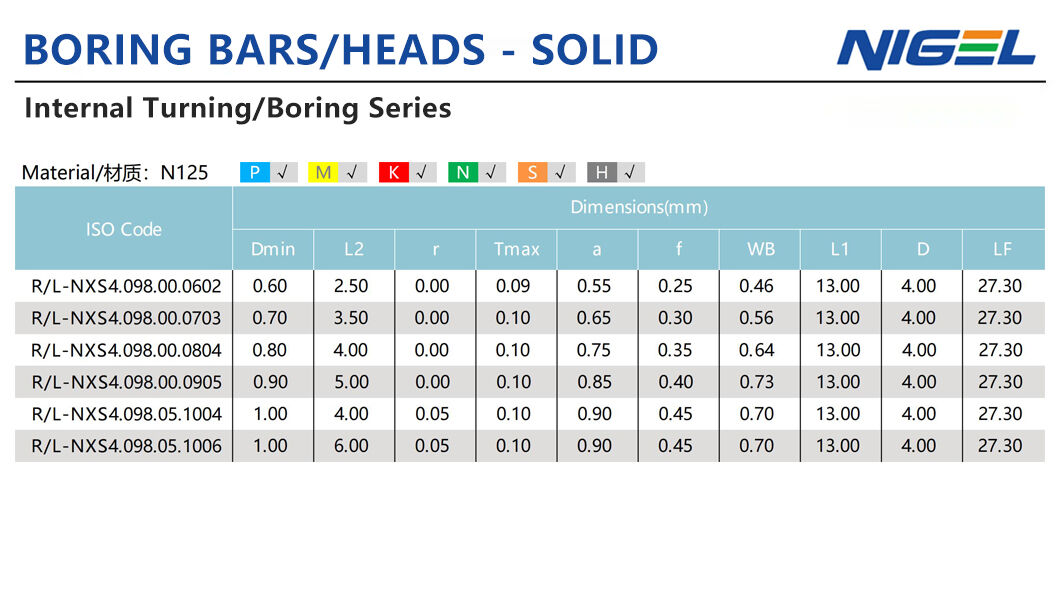

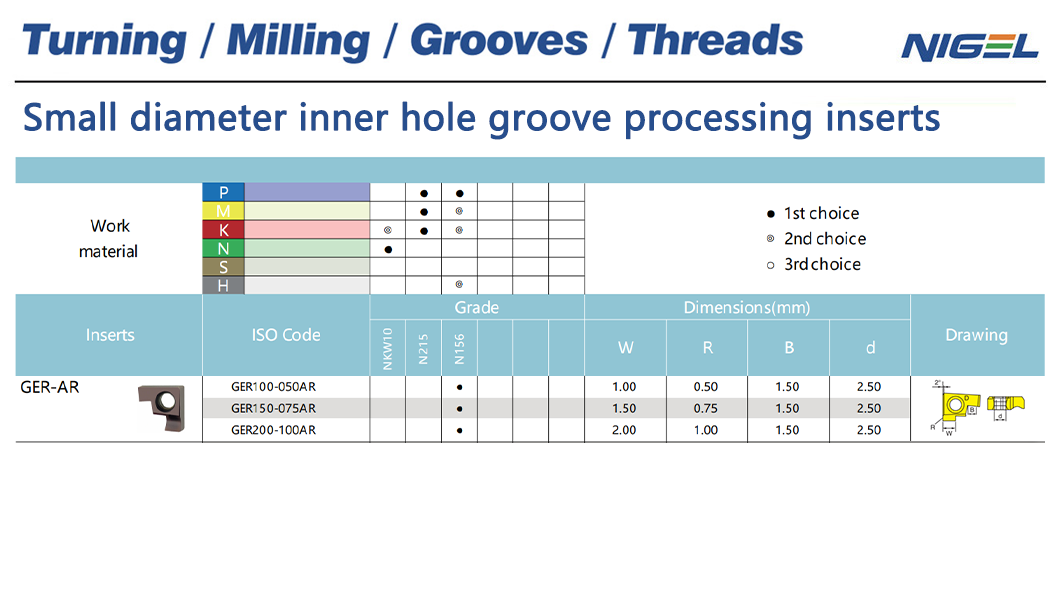

One of the reasons NIGEL carbide inserts are widely accepted is their versatility. This allows them to be employed in many different varieties of powder machining, including lathes, mills and drills. Thanks to this versatility, manufacturers can utilize carbide inserts on diverse projects, whether they are creating small precision parts or undertaking larger production runs. It makes grooving inserts an excellent option for different applications.

There are several essential aspects to keep in mind when you are making carbide inserts selection for your work project. One, there are three different shapes for the insert. There are multiple shapes of carbide inserts like triangular, square, circular, etc. The shape you select will be determined by what sort of cutting you want to do and what kind of machine you are using. Different shapes can help you accomplish different cutting outcomes.

How NIGEL Carbide Inserts Revolutionized the World of Manufacturing? Manufacturers are producing higher quality products in less time with the use of pcd threading inserts. Due to the durability of carbide inserts, carbide inserts can be used for longer until they need to be replaced. This minimizes downtime — that is, the time machines are not operational — and maximizes productivity — that is, the amount of work that is accomplished.

It also gives more streamlined cuts and help with refined finishes. It is particularly critical in sectors where accuracy is paramount: aerospace or medical manufacturing, for example. In these industries, producing parts and components to stringent quality specifications is a must. For these industries, NIGEL carbide inserts provide the guarantee that products are manufactured in a proper, safe manner.