Have you ever wondered how factories are able to create specific shapes and designs on материаls such as metal? They use many machines to accomplish this, one of which is a pcd insert lathe. A lathe is a specialized machine that spins a sample material on a pole as various tools carve out different shapes in it to create the required shape. A key part of this NIGEL machine is the lathe insert that determines the efficiency of the shaping process.

It is a small piece that assists in cutting the material. These bits can be made from various materials such as carbide, ceramic or high speed steel. An essential function of a lathe is the lathe insert, whose task is to remove excess material from a work piece to shape it according to the requirement. Update the shape and size of the NIGEL lathe insert, we can output all kinds of designs on various materials. This flexibility is key, as it enables manufacturers to produce anything from simple parts to complex designs, depending on their needs.

There are a few significant factors to consider while choosing the right lathe inserts for the job. You have to think about the sort of material you are using, how huge and in what shape the piece you have to work on is, and how precise you should be while cutting. This means those are some of the factors you will need to consider when choosing wnmg insert.

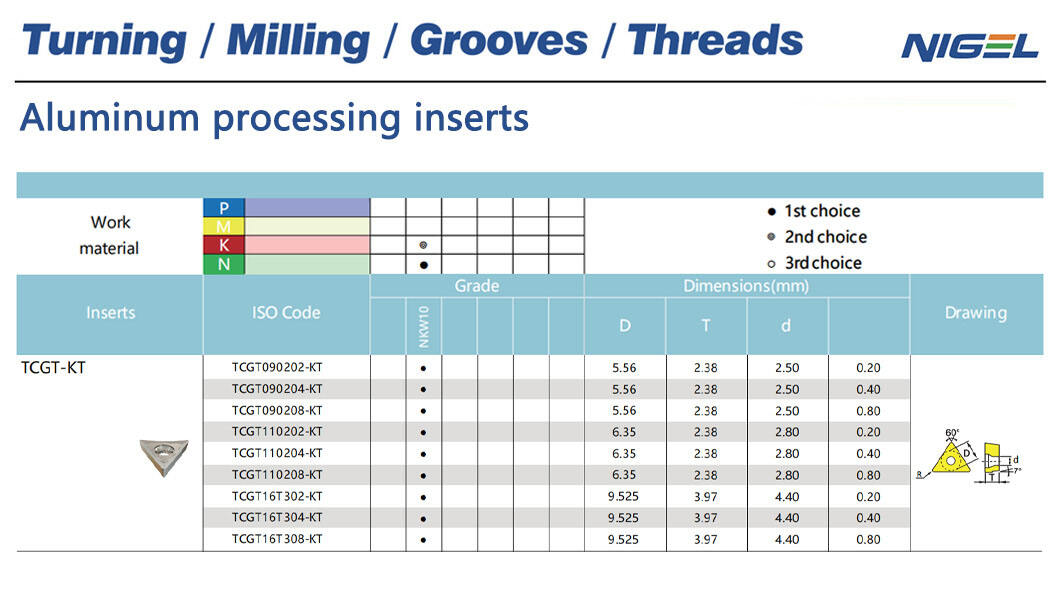

Carbide lathe inserts fall under ideal type when handling tough material like titanium. They can withstand the intense lashes of heat and pressure we get when we cut. It makes them long-lasting, high-performing utilities for hard jobs. If, in contrast, you are working with a softer substance like aluminum, you might find a high-speed steel grooving inserts to be more efficient. It is also important to select the appropriate insert for the material.

One major upside is that they speed things up at work. better inserts help factories reduce machining time, which translates into more parts per unit time. That means less waste and better-fitting parts, all of which is good for the process as a whole.