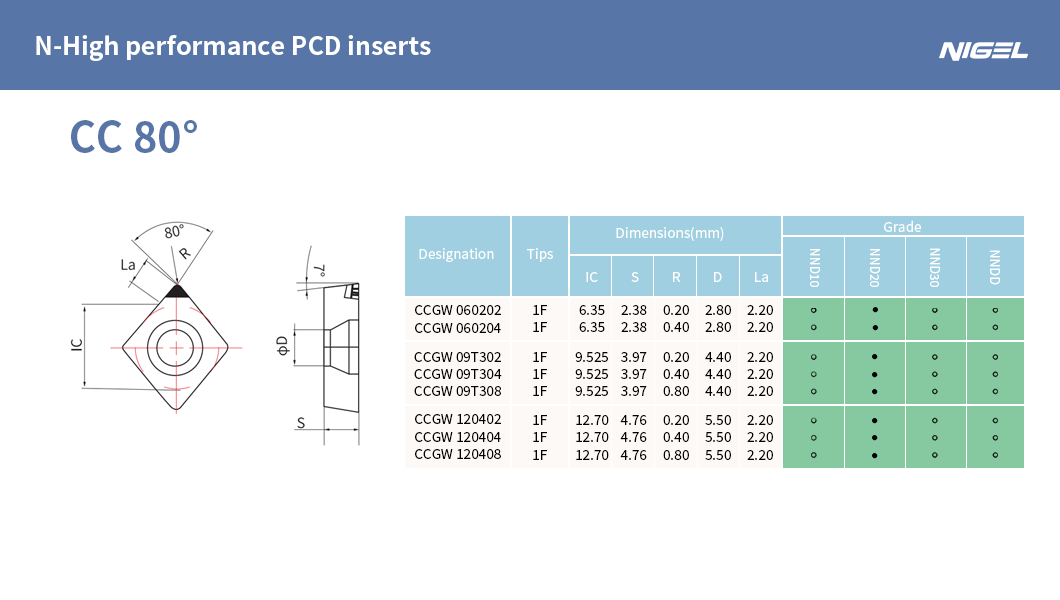

Involutes Diamond carbide inserts are one of the hardest and strongest tools used in precision tooling which simply helps the operator to reduce running expenses. These inserts are frequently employed in machining tools for shaping and cutting hard materials such as metal and composites. NIGEL the Specialist of Carbide Tipped Diamond Shape Inserts.. considered as a Quality And Durable Product.

The diamond shaped carbide inserts are constructed using an extremely durable material known as carbide, which has high hardness and provides resistant to wear. Shaped correctly in diamond pattern, these inserts will easily shear through any material. This distinctive shape provides precision machining more efficiently.

Munitions-grade equipment won't do for when you need precision engineering there's no substitute for precision tools. Tetra shaped carbide inserts are made to fulfill such demands with a sharp edge that retains for a longer period. It provides that every cut is sharp, smooth and of high quality so that you can produce high quality finished products every time.

In the realm of manufacturing, efficiency is the name of the game. Carbide inserts shaped like a Diamond significantly increase productivity by decreasing machining time and energy consumption. Their sharp cutting edges and very dry performance reduces the machining times during your applications and increases your cutting tool lifetimes, so that you save time and money.

When using a DIAMOND shape carbide insert the user should follow the manufacturer guidelines on proper tooling and machining practices. This will ensure the inserts are at their peak performance and will achieve the results you want. By maintaining such potent assets in tip-top condition, manufacturers can continue to gain from enhanced productivity and finer engineering.