Want to get your manufacturing working much better and more smoothly? Carbide inserts are round, have you heard of it? These are just tiny, round tools that work magic in manufacturing processes. This text will familiarize the round carbide inserts with the advantage they deliver in making machine work faster along with efficient and precise working characteristics

What is the benefit of using these tools? One major benefit is that they last a long time. This means you shouldn’t have to buy new ones much. The longer something lasts, the more money you'll save in the future, since you wouldn't need to keep replacing them. This cubic boron nitride inserts is good news for business as it aids in cost control. The second advantage is that, the round carbide inserts can cut faster than other tools. This velocity allows things to be making in a timely manner, something crucial within the production industry where money is time.

High-speed machining is a unique process in which machines run at very fast conditions to fabricate and manufacture parts. This type of high-speed machining requires round carbide inserts. They are tough and resistant enough to withstand the high speeds and pressures required in the process. This lathe inserts also allow manufacturers to get their work done more quickly, facilitating greater productivity and timeliness

Besides, round carbide inserts help bring manufacturing efficiency and accuracy. They are built to provide consistent results every time, which is extremely important for companies making parts that must fit exactly. Even the smallest variance can have serious down line implications, which is why consistency is critical in manufacturing.

The use of these inserts also lowers the risk of making errors and producing defects. Common practice in industry that results in defects can eerily appear when there are mistakes. Reason why round carbides inserts are used: Helps manufacturers in achieving better results. This index drill accuracy ensure high quality products, making customers happier in the end. Satisfied customers will return and make more purchases.

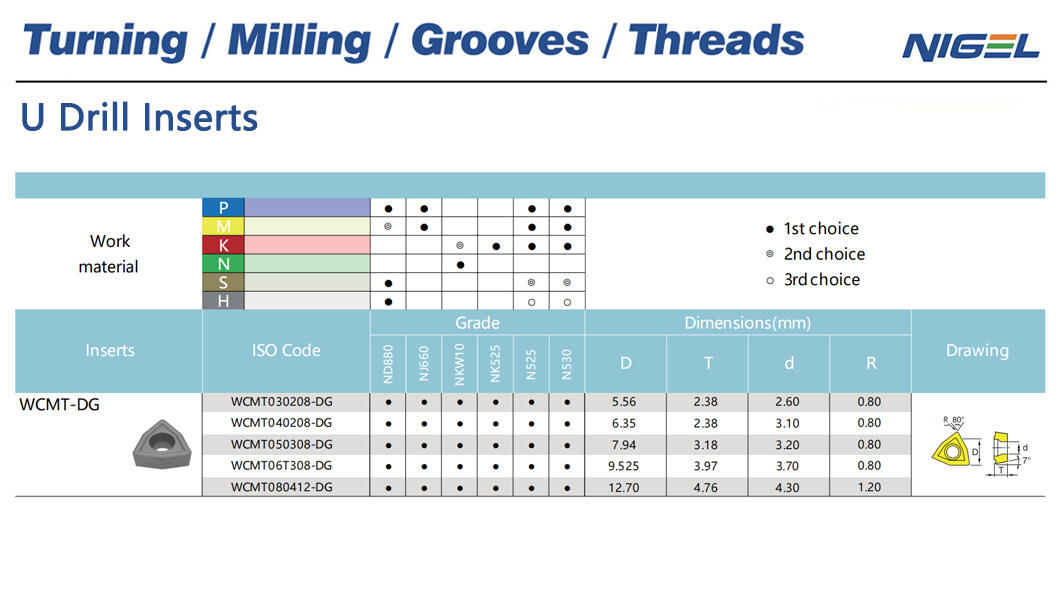

There are many advantages of using round carbide inserts for cutting and shaping materials. They are usually more durable than other tools so you need to u drill inserts spend less time maintaining them. This helps save money and minimizes downtime in production. If a machine has to stop working for replacing a tool, that can slow down the entire production process.

In addition, round carbide inserts can achieve faster cutting speeds. It's an enabler of much faster manufacturing processes, which can be critical at peak times of high demand. Another key is that they give you uniform & accurate outputs. This tungsten carbide inserts is particularly significant for companies that manufacture parts that need to fit together perfectly. Thus, it is not hard to see why round carbide inserts are the way to go when it comes time to cut and shape materials.