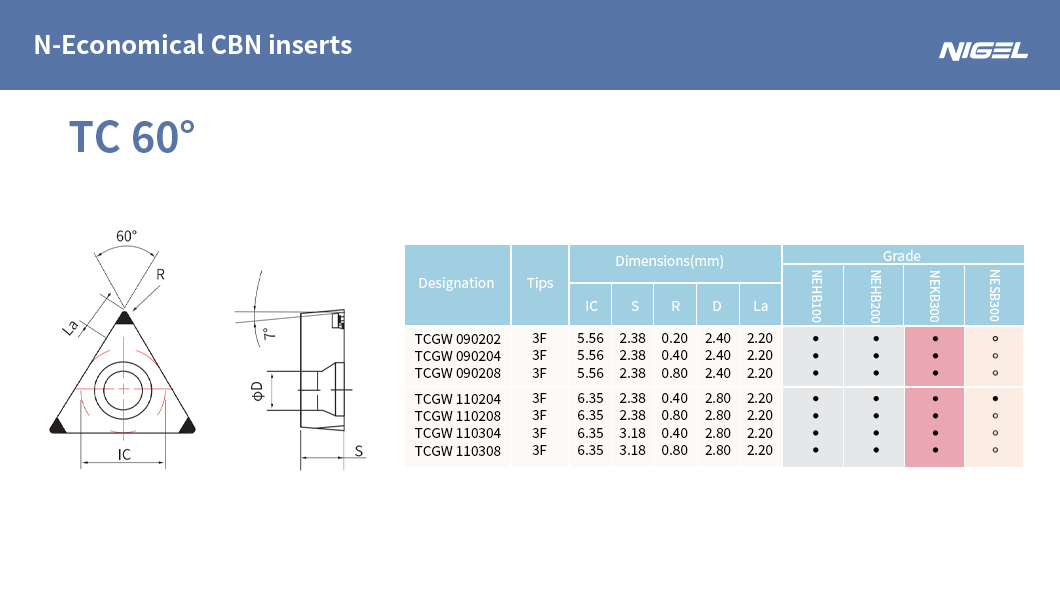

Introducing PCD (Polycrystalline Diamond) threading inserts from NIGEL, the latest innovation in thread cutting. PCD stands for polycrystalline diamond. In other words, the inserts are made of tiny bits of diamond that are fused in pressurized applications with extreme heat. PCD/CBN Inserts are extremely hard and very durable, which is what makes them so unique and useful. To start with is their inherent hardness, they can cut through some pretty tough materials (such as titanium, Inconel, and hardened steel), making them a great tool for a number of machining applications.

It is a very important aspect of manufacturing for many machines and tools. It creates threads, the spiraled sections that enable various parts to interconnect seamlessly. Good threads are what is needed, as they help ensure that products function properly and as safe for users. Using normal thread cutting tools is quite difficult to get reasonable shape and size thread. With PCD Boring Inserts, making accurate and smooth threads becomes significantly less of a challenge. This ensures the final product functions properly and survives for a longer duration.

The ability for NIGEL PCD threading Turning Inserts to produce threads quickly is a huge advantage. They can maintain a high accuracy rate even when they work at this speed, which allows workers to complete more tasks in the same period of time and is particularly useful in the busy environments of manufacturing. PCD inserts are also made to remain sharp when they heat up considerably during the cutting process. This means that they do not have to be substituted as frequently, minimizing downtime among employees. PCD inserts also perform well with both coolant water methods and dry cutting methods where water is not used. This flexibility enables workers to consider the job they are doing and decide how to best make the cut.

PCD threading inserts are especially special when it comes to cutting tough materials. When it comes to drilling through hard materials like titanium and hardened steel, regular threading tools have a hard time performing. These materials require significant force to cut through and can produce significant heat which could damage the tool. PCD inserts, on the other hand, are designed to endure such critical environments. This allows them to slice right through even the toughest materials with precision, significantly simplifying and speeding up the process for workers.

PCD threading inserts is a good investment for the companies. These U Drill Inserts far outlast conventional cutting tools. They have a longer lifespan, requiring less frequent change, saving time and lowering wait time in production. That also means there’s less money spent on getting new tools. In addition, PCD inserts save money because certain materials need additional costly processes such as grinding and finishing after cutting. Customers can also achieve high-quality threads while maximizing their productivity and minimizing their costs by selecting NIGEL PCD threading inserts.