Introduction:

The advantages of ceramic inserts include high hardness and wear resistance, and are suitable for processing high-hardness materials such as cemented carbide, hardened steel, etc.

Ceramic inserts have high thermal stability and thermal shock resistance, and can maintain good dimensional stability during high-speed cutting.

In addition, ceramic inserts also have good self-sharpening properties, are not easy to stick to the blade during cutting, are suitable for dry cutting, reduce the use of cutting fluid, and are environmentally friendly.

However, the disadvantages of ceramic inserts mainly include brittleness and poor impact resistance, and are prone to breakage or cracks during cutting.

Due to the high brittleness of ceramic materials, it is easy to collapse and break during processing, so special attention should be paid to avoid collision and impact during use.

In addition, the installation and replacement of ceramic inserts are relatively complicated, and special fixtures and tools are required, which increases the difficulty and cost of operation.

In summary, ceramic inserts have the advantages of high hardness, wear resistance, and good self-sharpening properties, and are suitable for processing high-hardness materials, but during use, attention should be paid to their brittleness and poor impact resistance, and collision and impact should be avoided to ensure processing results and tool life.

| Inserts ISO Code | Grade | Dimensions(mm) |

| VBMT110302-HQ | DNW100 | D: 6.35 / T: 3.18 / d: 2.80 / R: 0.20 |

| VBMT110304-HQ | DNW100 | D: 6.35 / T: 3.18 / d: 2.80 / R: 0.40 |

| VBMT110308-HQ | DNW100 | D: 6.35 / T: 3.18 / d: 2.80 / R: 0.80 |

| VBMT160402-HQ | DNW100 | D: 9.525 / T: 4.76 / d: 4.40 / R: 0.20 |

| VBMT160404-HQ | DNW100 | D: 9.525 / T: 4.76 / d: 4.40 / R: 0.40 |

| VBMT160408-HQ | DNW100 | D: 9.525 / T: 4.76 / d: 4.40 / R: 0.80 |

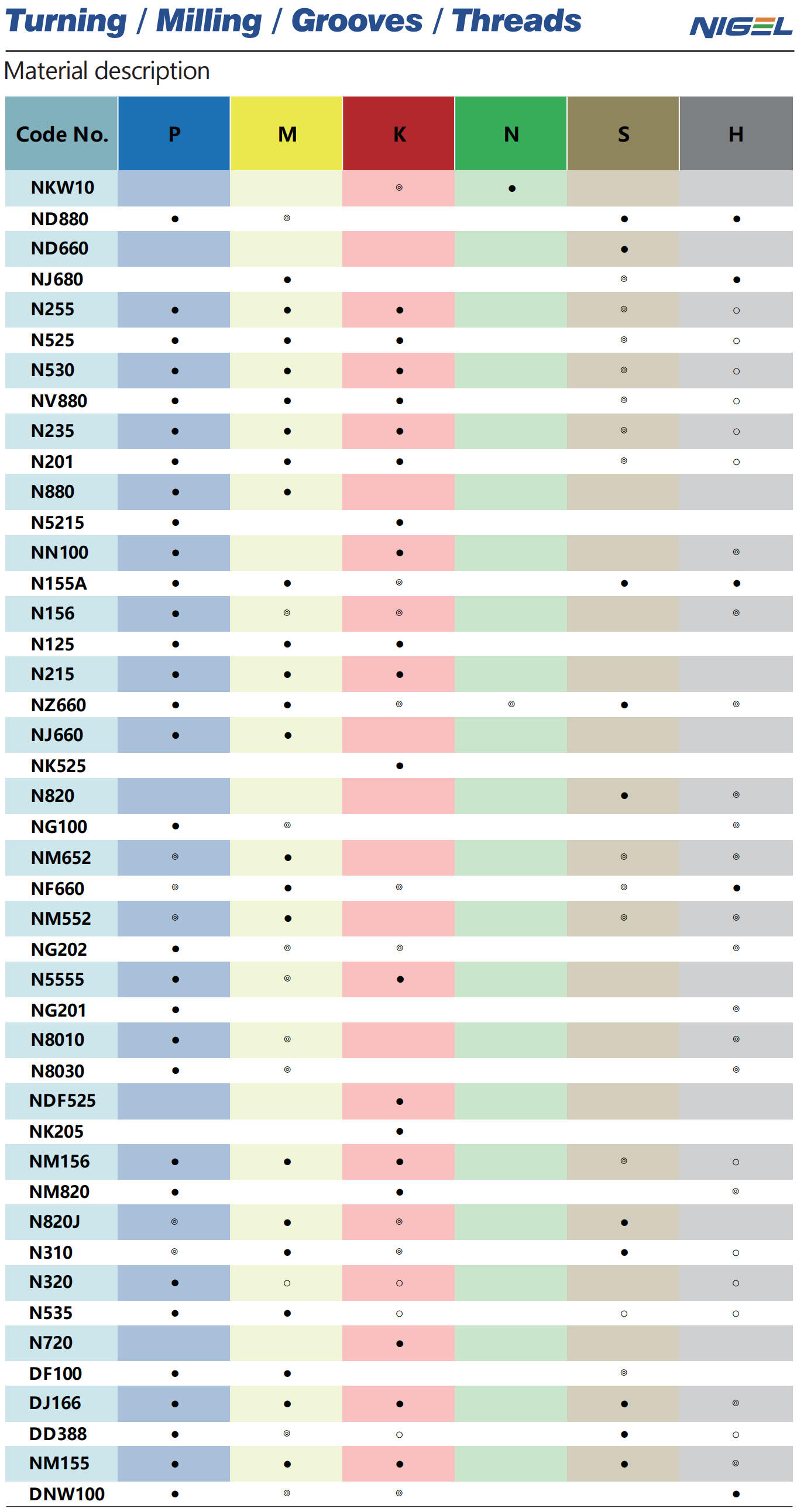

Grade Reference: