Introduction:

Precision:

Groove machining inserts are engineered to produce grooves with high accuracy, maintaining tight tolerances essential for critical applications.

Multiple Configurations: Groove inserts are available in various geometries and sizes, making them adaptable to different groove shapes and dimensions.

Wear Resistance:

Advanced coatings and optimized designs enhance the durability of groove machining inserts, leading to longer tool life and reduced need for frequent replacements.

Smooth Grooves:

They provide high-quality surface finishes, which are vital for parts that require precise fits or aesthetic considerations.

Reduced Tooling Costs:

Their extended lifespan and ability to handle various materials lower the overall tooling costs.

| Inserts ISO Code | Grade | Dimensions(mm) |

| DGN2002-C | N255 / N525 | L: 19.90 / T: 2.00 / R: 0.20 |

| DGN2202-C | N255 | L: 19.80 / T: 2.20 / R: 0.20 |

| DGN3002-C | N255 / N525 | L: 20.90 / T: 3.00 / R: 0.20 |

| DGN3102-C | N255 | L: 20.10 / T: 3.10 / R: 0.20 |

| DGN4003-C | N525 | L: 18.80 / T: 4.00 / R: 0.30 |

| DGN5004-C | N525 | L: 19.10 / T: 5.00 / R: 0.40 |

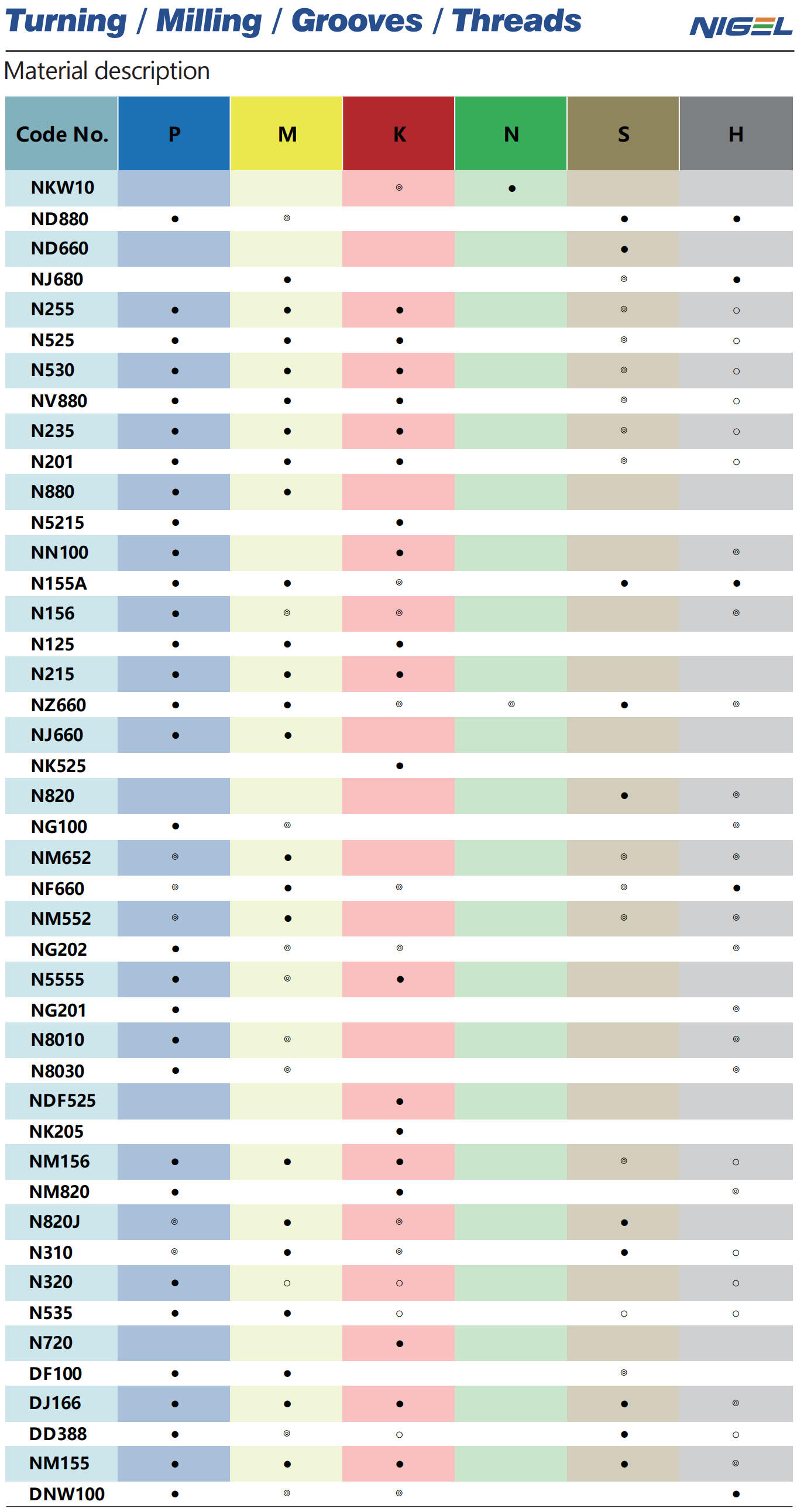

Grade Reference: