Introduction:

High-Speed Machining Capabilities

Carbide inserts are capable of withstanding the high speeds required for efficient aluminum machining. Aluminum’s softness allows for rapid material removal, and carbide's hardness and thermal stability ensure that the inserts can maintain their cutting edge at high speeds, resulting in faster cycle times and improved productivity.

Excellent Wear Resistance

Aluminum’s tendency to create a build-up of material on the cutting edge (BUE) can be problematic. High-quality carbide inserts often come with advanced coatings or specially treated surfaces that minimize BUE, maintaining sharpness and extending the tool life. This wear resistance is crucial for achieving consistent, high-quality finishes on aluminum workpieces.

Superior Surface Finish

Carbide inserts produce exceptional surface finishes on aluminum due to their precision-ground edges and ability to maintain sharpness throughout the cutting process. This is particularly important for industries where the surface integrity and appearance of aluminum components are critical, such as in the aerospace and automotive sectors.

Improved Chip Control

Effective chip control is essential when machining aluminum to prevent damage to the workpiece and ensure a smooth operation. Carbide inserts are designed with specialized geometries that facilitate optimal chip evacuation, reducing the risk of clogging and ensuring a cleaner cutting environment.

| Inserts ISO Code | Grade | Dimensions(mm) |

| CNGG120402-KT | NKW10 | D: 12.70 / T: 4.76 / d: 5.16 / d: 0.20 |

| CNGG120404-KT | NKW10 | D: 12.70 / T: 4.76 / d: 5.16 / d: 0.40 |

| CNGG120408-KT | NKW10 | D: 12.70 / T: 4.76 / d: 5.16 / d: 0.80 |

| CNGG120412-KT | NKW10 | D: 12.70 / T: 4.76 / d: 5.16 / d: 1.20 |

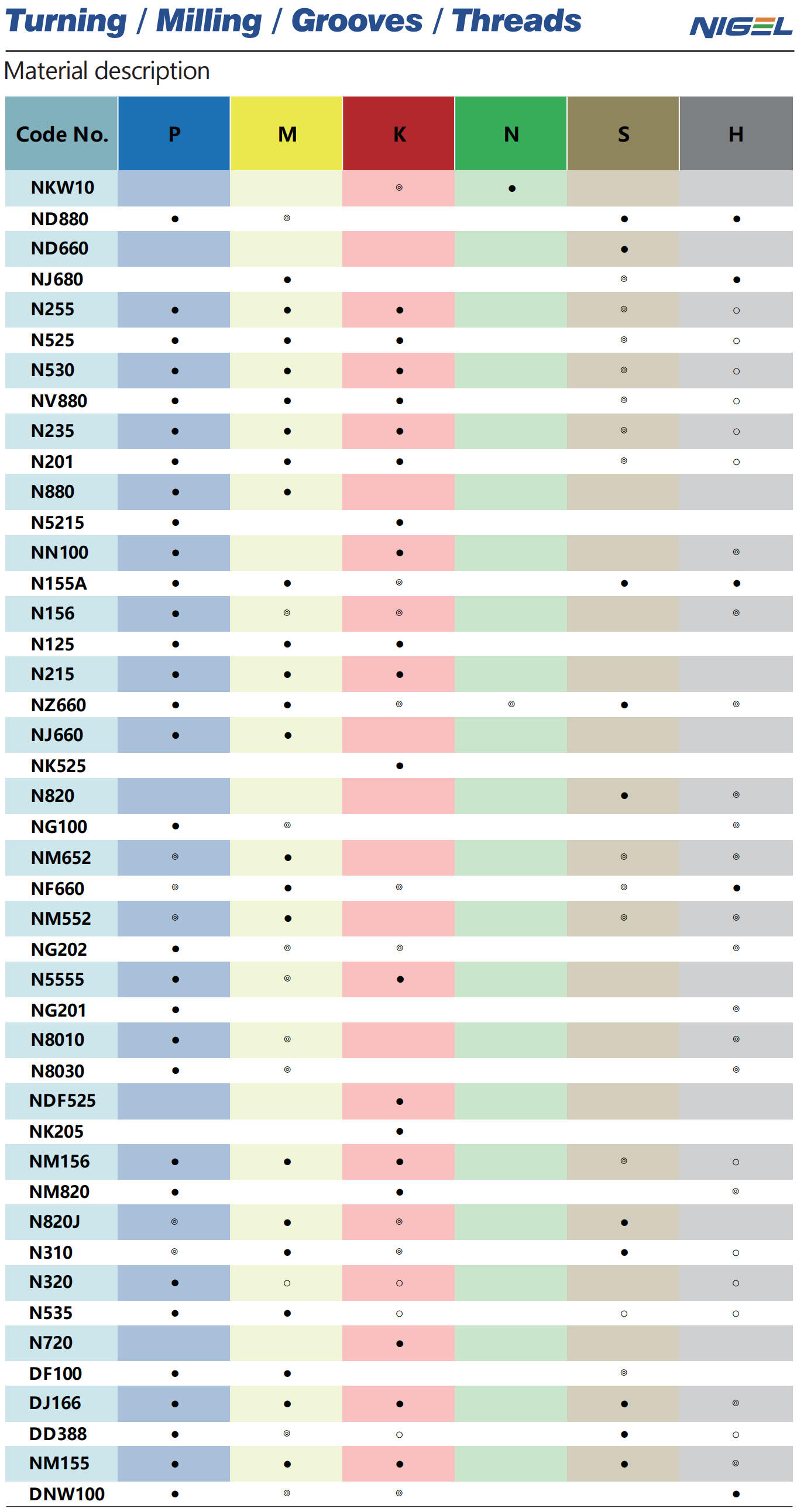

Grade Reference: