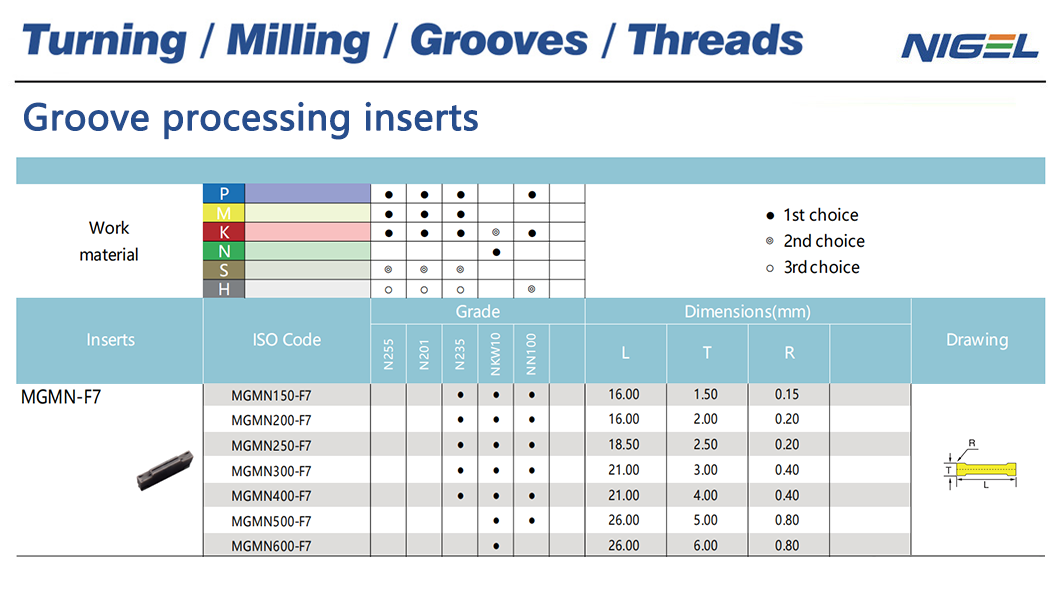

Did you know that cutting grooves with the help of a special equipment, the groove insert lathe, can make this process a lot easier and more accurate?, we’ll take a look at how Groove insert lathes can help improve production efficiency. Let's dive in!

Groove insert lathes are a class of machine tools for cutting grooves into workpieces such as wood or metal. The machines have special inserts that ensure fast and accurate cut. By implementing a groove insert lathe, manufacturers can save money and time by cutting out a significant amount of manual labor involved in cutting grooves.

One of the advantages of having a groove insert lathe is the kind of cuts you can make with ease. The lathe inserts are cut for precision and the finish is to tolerance for the inserts specified. This level of accuracy is very important in industry, since even the smallest error leads to enormous effort.

In addition to precision cutting, groove insert lathes also provide excellent all around grooving. The inserts for the lathe are constructed of sturdy materials that can survive the pressure of cutting hard substances. The result: perfectly cylindrical grooves and precise returns – machined with the quality standards being synonymous with the machinery “Made by GEHRING” region.

With a high production groove insert lathe, builders can increase efficiency and production levels. These work at high speed and yet offer good accuracy levels, thus more grooves can be cut faster. This added efficiency can assist businesses in completing deadlines and orders.

In general, a groove insert lathe is beneficial, because it can allow manufacturers to produce more precision and quality fitting pieces. Because they can produce precise grooves at high speeds, most products can be cut by companies at the most exacting job specifics. With a groove insert lathe from NIGEL, you can elevate your manufacturing process for industry leading results and to always be at the cutting edge of the competition.