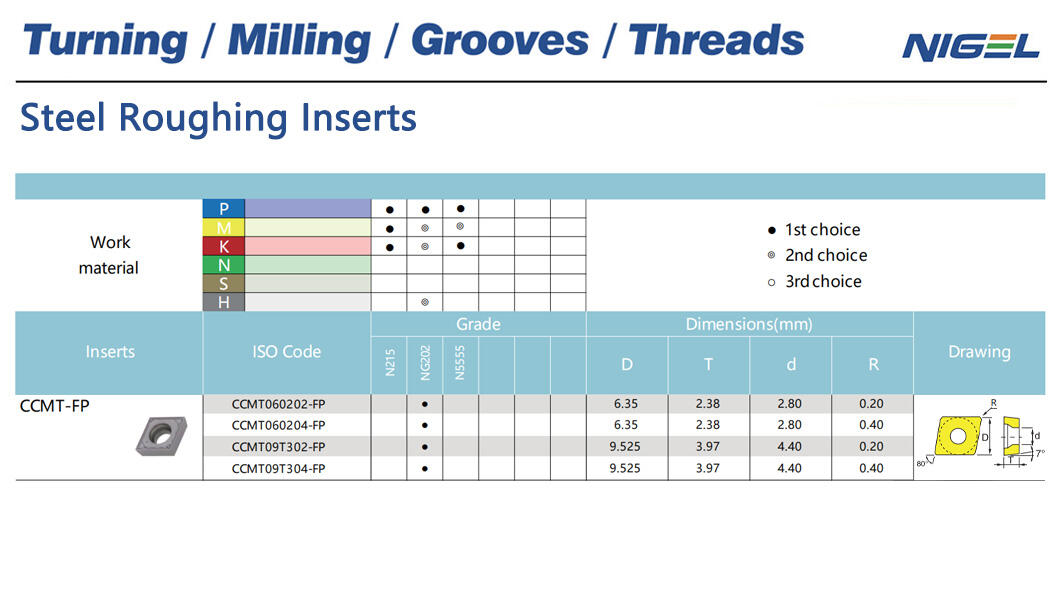

Common turning insert profiles: CCMT 32.51. Turning tool inserts are used in lathes for precision machining. The model stands durable due to the strong materials used for its construction, which make this cut well through different materials. The name “32.51” describes the size and shape of the insert, so it’s easy to identify and use in a wide range of lathes.

Mastering the CCMT 32.51 turning insert also requires knowing how to use it properly. It needs to be attached with safety on your lathe when using this tool. In addition, adjusting the lathe's speed and feed rate will help you achieve precise cuts and smooth finishes on the materials you are working with.

CCMT 32.51 Inserts and Their Many Benefits for Lathe These are precision-cut material inserts that provide smoother finishes and create less waste. They also assist the lathe in its work, which saves your time and allows more productive machining operations.

TOP TIPS FOR GETTING THE BEST FROM CCMT 32.51 INSERTS. For one, always make sure that the insert you are using is sharp and in a good condition before its application on the lathe. This will allow you to get nice, clean cuts and it will extend the life of the insert. Adjust for best insert performance on the material you are using by also adjusting the cutter and depth of cut.

Special features of the CCMT 32.51 insert make it advantageous in various machining applications. This is because inserts are typically used for turning and facing operations on lathes, enabling you to achieve high precision on steel, aluminum, and other metals. Understanding CCMT 32.51 insert characteristics will help you select the appropriate tool for the job and obtain the desired results.