Introduction:

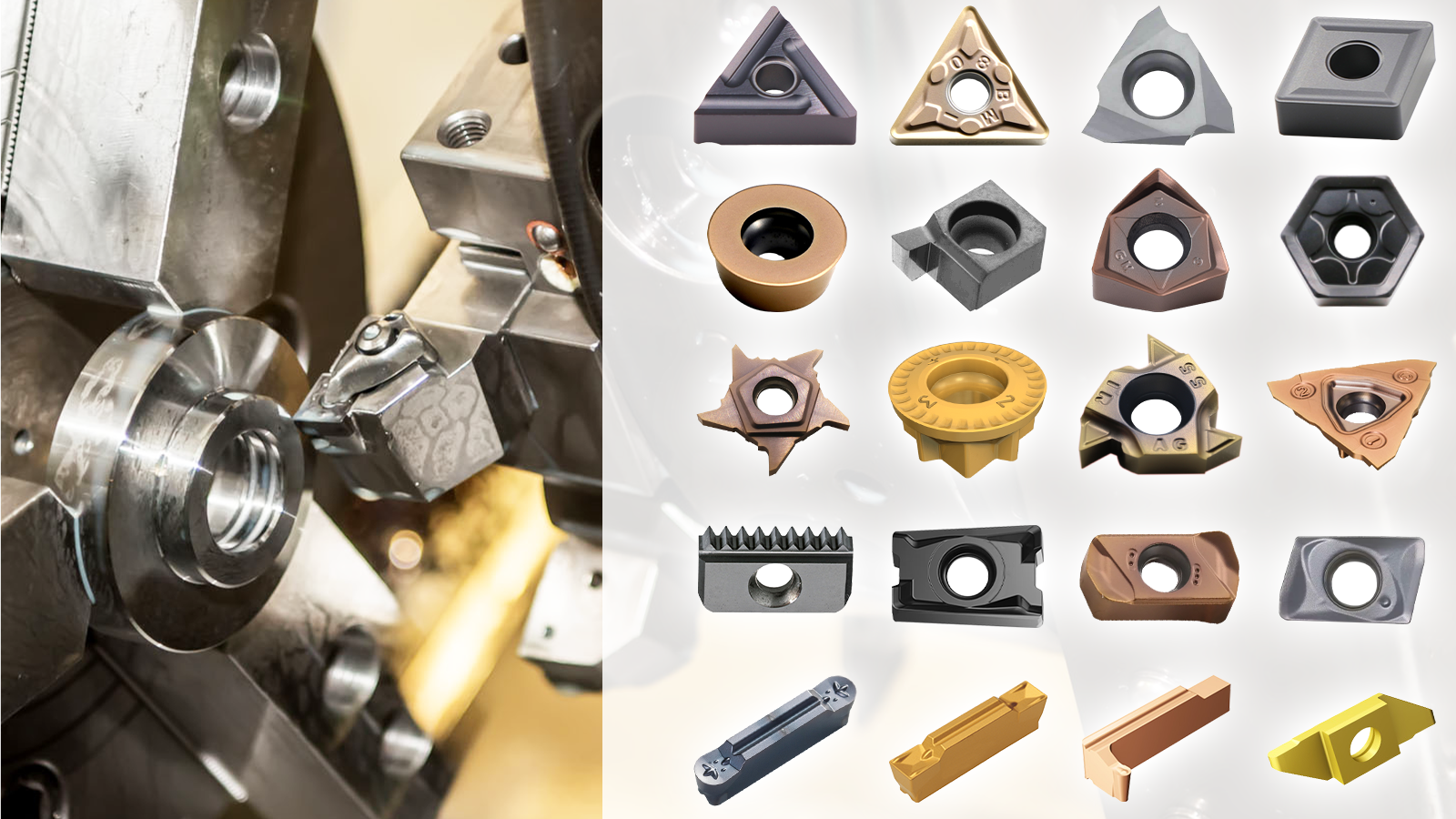

Boring inserts are specialized cutting tools used primarily in the boring process, which involves enlarging and finishing the diameter of an existing hole. These inserts are designed to provide high precision, excellent surface finish, and efficiency in material removal.

Advantages of Boring Inserts

Precision and Accuracy:

Boring inserts are engineered to achieve precise diameters and roundness, maintaining tight tolerances essential for high-precision applications.

Surface Finish:

Capable of delivering excellent surface finishes, reducing the need for secondary finishing operations.

Versatility:

Suitable for a broad spectrum of materials, including both metallic and non-metallic workpieces.

Optimized Chip Control:

Designed to provide effective chip breaking and evacuation, which enhances machining efficiency and surface quality.

Heat Resistance:

Capable of withstanding the high temperatures generated during machining, which further extends their lifespan.

Coatings:

Many boring inserts are coated with materials like titanium nitride (TiN), titanium carbonitride (TiCN), or diamond-like carbon (DLC) to improve wear resistance and performance.

Geometry:

Advanced insert geometries are available to optimize chip control, surface finish, and tool life for specific materials and applications.

| Inserts ISO Code | Grade | Dimensions(mm) |

| WBGT060101L | N156 / NN100 | D: 3.97 / T: 1.59 / d: 2.30 / R: 0.10 |

| WBGT060102L | N155A / N156 / NN100 / NZ660 | D: 3.97 / T: 1.59 / d: 2.30 / R: 0.20 |

| WBGT060104L | N155A / N156 / NN100 | D: 3.97 / T: 1.59 / d: 2.30 / R: 0.40 |

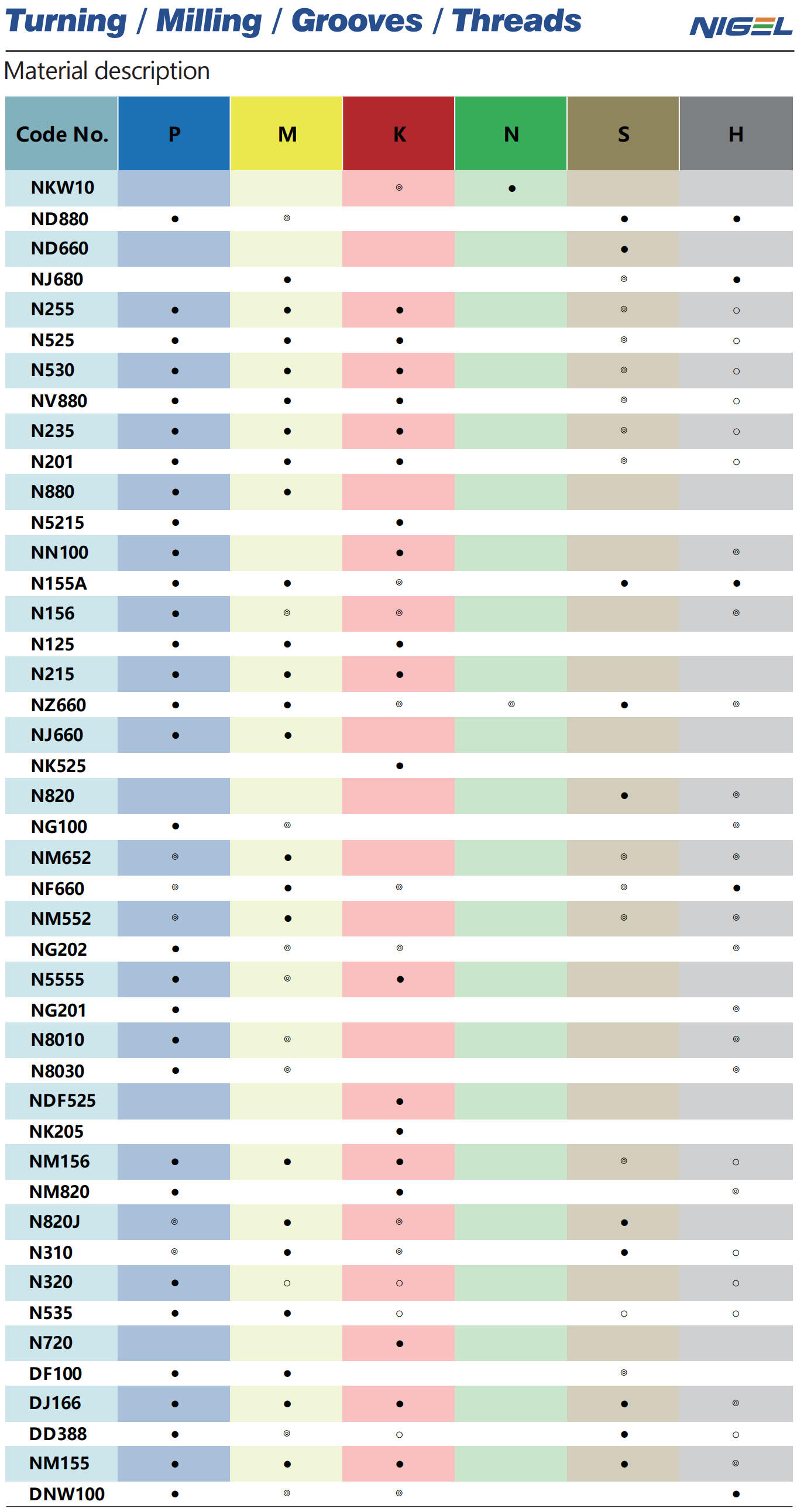

Grade Reference: