Introduction:

PCD (Polycrystalline Diamond) and CBN (Cubic Boron Nitride) are both types of superhard cutting tool materials, but they have different properties which make them suitable for different applications. Here are the primary differences:

Composition and Hardness:

PCD is one of the hardest known materials, second only to diamond. CBN comes next in hardness. PCD is made by sintering diamond particles with a metal binder at high temperature and pressure, while CBN is made by treating boron nitride at extremely high temperature and pressure.

Application of Use:

PCD inserts are typically used for cutting non-ferrous and non-metallic materials like aluminum, brass, copper, plastic, wood, and rubber. On the other hand, CBN is typically used for cutting hardened steel, cast iron, and other hard ferrous materials.

Heat Resistance:

CBN has high resistance to heat compared to PCD. This makes CBN suitable for high speed machining of ferrous materials which generate high cutting temperatures.

Wear Resistance:

Both insert types have excellent wear resistance, but CBN is more suitable for machining ferrous materials due to its superior hot hardness and chemical stability under cutting conditions.

Cost:

Generally, CBN inserts are often more expensive than PCD. However, the selection should be based on the material to be machined and the specific machining requirements rather than cost alone.

In summary, the choice between PCD and CBN depends largely on the workpiece. If it's a non-ferrous or non-metallic material, PCD would be the suitable choice. However, for hard, ferrous materials, CBN would be more suitable.

| N-High performance CBN inserts | N-Economical CBN inserts | N-High performance PCD inserts |

| TPGW 080202 | TPGW 080202 | TPGW 080202 |

| TPGW 080204 | TPGW 080204 | TPGW 080204 |

| TPGW 080208 | TPGW 080208 | TPGW 080208 |

| TPGW 090202 | TPGW 090202 | TPGW 110302 |

| TPGW 090204 | TPGW 090204 | TPGW 110304 |

| TPGW 090208 | TPGW 090208 | TPGW 110308 |

| TPGW 110204 | TPGW 110204 | TPGW 160302 |

| TPGW 110208 | TPGW 110208 | TPGW 160304 |

| TPGW 160308 | ||

| TPGW 110302 | TPGW 110302 | |

| TPGW 110304 | TPGW 110304 | TPGW 160402 |

| TPGW 110308 | TPGW 110308 | TPGW 160404 |

| TPGW 160408 | ||

| TPGW 160302 | ||

| TPGW 160304 | TPGT 080202 | |

| TPGW 160308 | TPGT 080204 | |

| TPGT 080208 | ||

| TPGW 160402 | ||

| TPGW 160404 | TPGT 110302 | |

| TPGW 160408 | TPGT 110304 | |

| TPGT 110308 | ||

| TPGT 160302 | ||

| TPGT 160304 | ||

| TPGT 160308 | ||

| TPGT 160402 | ||

| TPGT 160404 | ||

| TPGT 160408 |

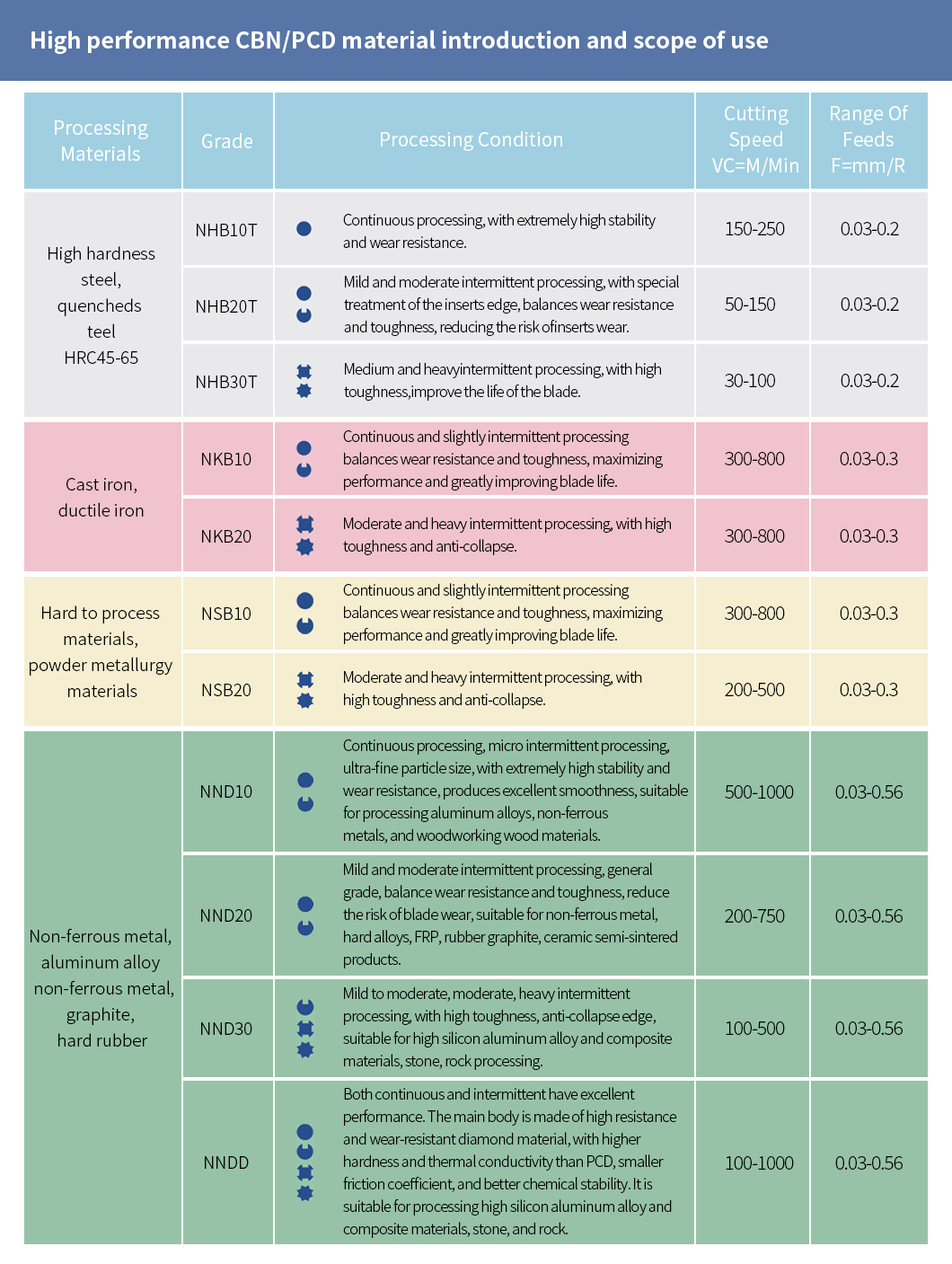

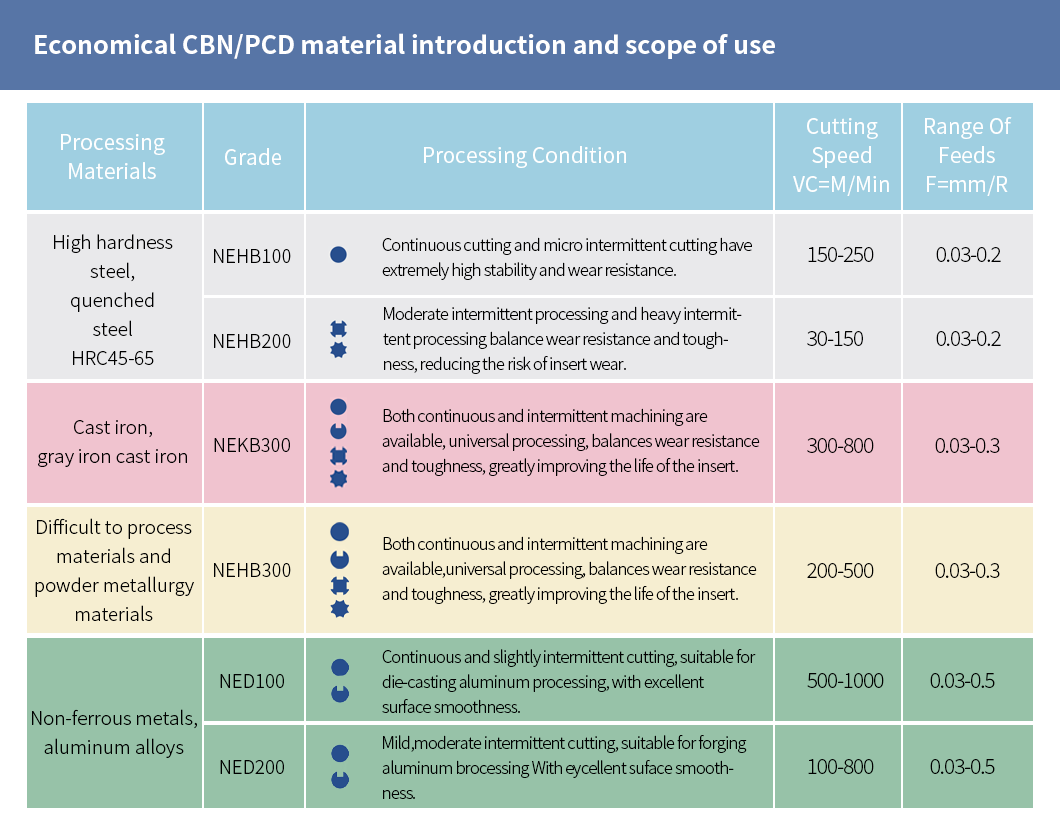

Grade Reference: