It is a small part made of a superhard metal (tungsten) and fitted to your clubhead. They are also used to improve tools and machines. These are used for cutting metal and other materials extreme precision. They ensure that the products being produced are good quality and are produced at a rapid pace.

This is like Tungsten inserts that make you fit into all these cutting tools and machines. They're extremely strong and heat-resistant. They’re also resistant to wear and tear, so they last a long time. These attributes make them ideal for factories where they must cut through tough materials.

Are Tungsten Inserts Common in Bit Designs?

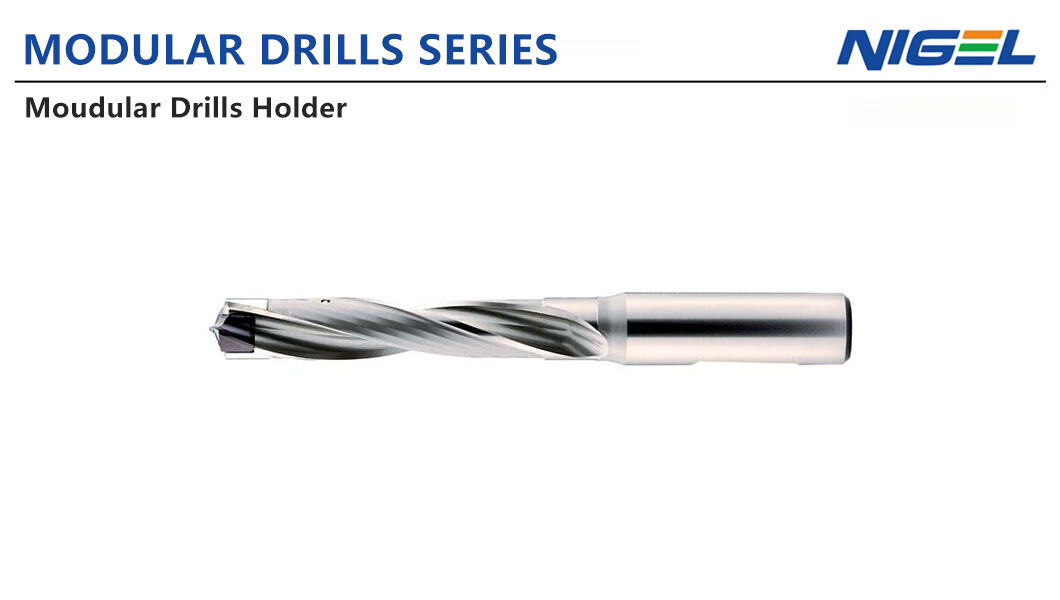

Tungsten inserts make drill bits work better and last longer when added to them. Tungsten also adds to the hardness of our drill bits, so they stay sharper longer. It means they don’t need replacing as often, saving money and enabling more productive work.

Tungsten Inserts are available in various shapes and sizes. (Some are triangular or squared, others are round or rectangular. The style and size of the insert are selected according to the required cutting, allowing the tools to function well.

However, their efficiency highly depends on the quality and performance of threading inserts. The block inserts are bad the tools can not cut well, Cause wear very quickly, The products made can be bad. With the help of Premium quality tungsten inserts from NIGEL, factories can ensure that their tools perform at their maximum potential, achieving great outcomes whenever they are used.