So, before going into the details of how to get the best prices on NIGEL PCD inserts, let’s take a quick look at where they; what they are, and why its significance. What is PCD (Polycrystalline diamond)? PCD full means polymer matrix composites this is solid material which is used to make PCD inserts. These tiny components have a massive contribution to machining since they aid in cutting and shaping various materials.

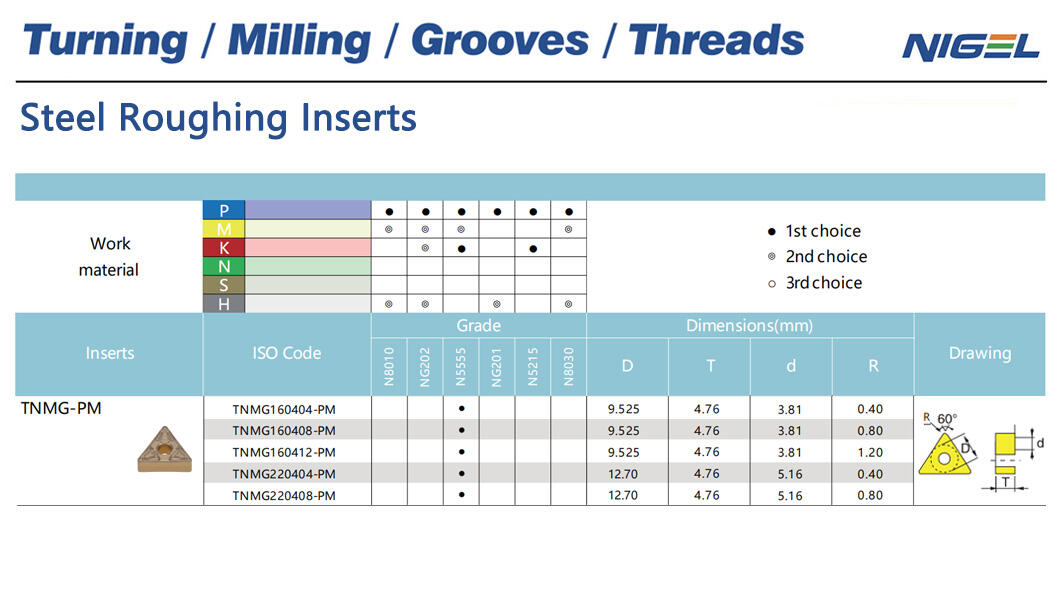

Understand What You Need – It is deeply important for you to be aware of what you need for your machining tasks before even looking for prices. Consider what kind of material you will process, how smooth the final surface you want to touch and the machining speed you want to achieve. With this knowledge you can sort through PCD grooving inserts and think of the right one for your work.

Do Your Research — After you have a clear understanding of what you want next step would be to research different suppliers and their prices. It is important to choose such suppliers who are specialized in NIGEL PCD inserts and known for its higher repute into the industry. You can visit their websites and see what kind of products they provide and what the prices are. Remember to check their social media pages also as they may provide valuable information there.

Mistake 1: Not shopping around for the right NIGEL PCD Insert Price: Both quality and cost are two fundamental reasons why you should shop around for a PCD milling inserts price. Quality is critical in machining as it helps to make sure that everything's being run properly and also within specifications. Cost is important because it directly impacts the money you have available to spend on your projects. So, striking a balance between quality and cost is essential for making wise purchases.

However, when you have to explore few choices and compare suppliers for the quality and cost of NIGEL PCD turning inserts it takes some time. This side-by-side comparison allows you to select the best device to suit your machining tasks and your finances. Moreover, it allows you to build a good relationship with the supplier. When a company forms a good relationship it may then lead to other deals and discounts in the future.

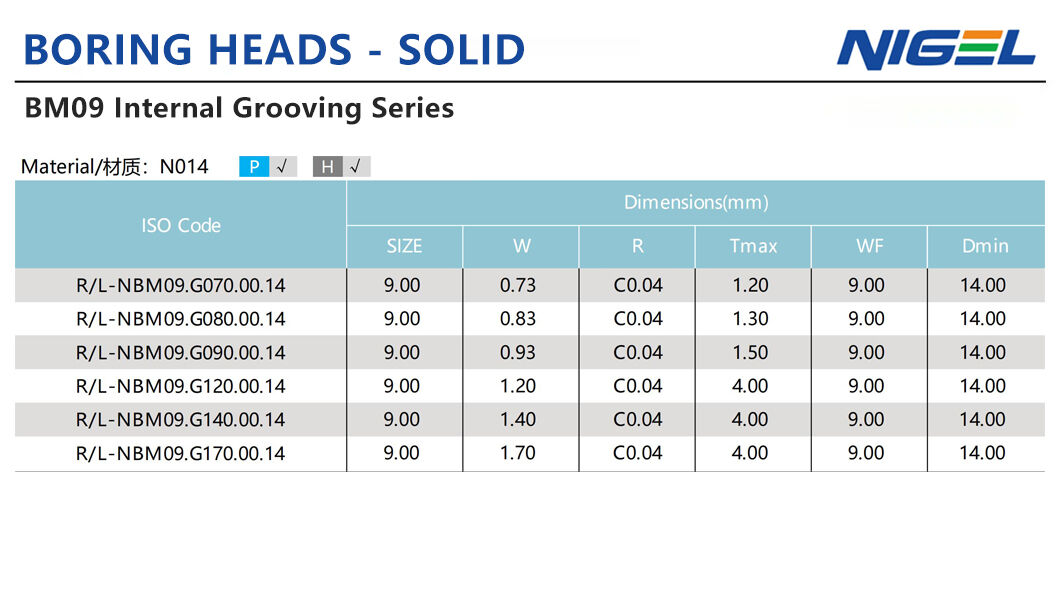

Select the Right Size and Shape – PCD inserts are available in several different dimensions and shapes. It is vital to select the one according to your precise machining requirements. It is essential to choose the correct size as an insert that is too large or small may not be efficient for your project. This may incur additional cost down the road when you have to replace them.