Ever wondered how things are made? Machines such as lathes — which shape and refine objects — help make many items we use daily. A tool referred to as a lathe inserts sits at the heart of a lathe. While this little tool may seem small but it is very essential for ensuring everything comes out just perfect.

Lathe Inserts- The steps of metal that fit into the lathe machine Conventional cutting which process various metals and woods. It would be hard, just try to draw a perfect circle without a compass! This is why lathe carbide insertss are handy. They help provide smooth surfaces and precise shapes to the objects we create.

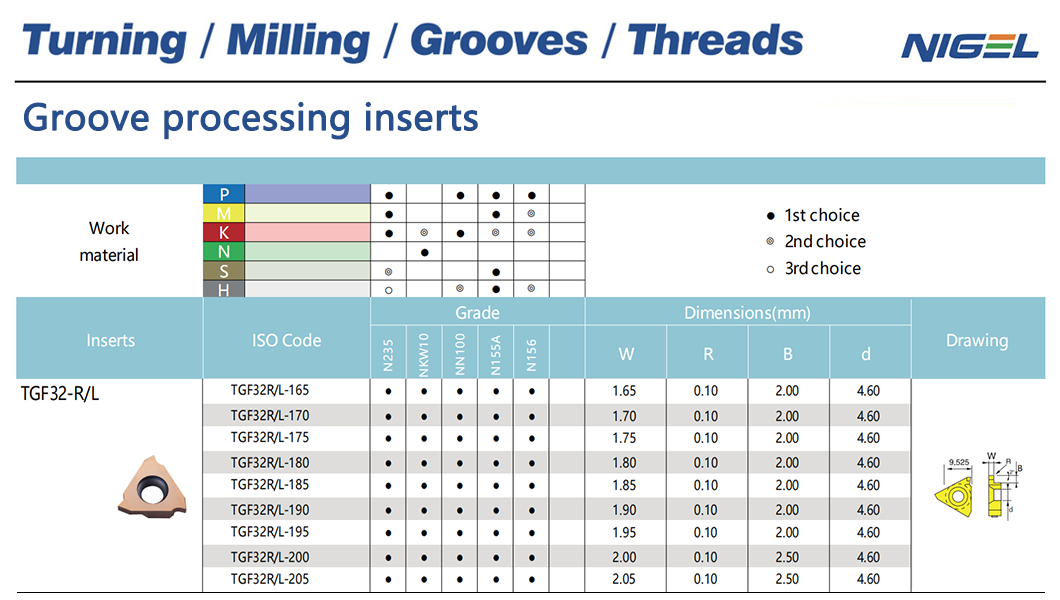

Lathe inserts are numerous and designed for each specific task. Some are meant for cutting hard materials such as steel, while others perform better on softer materials such as aluminum. Depending on what you are doing, you have to pick the right kind of lathe insert for your task.

Making good use of lathe inserts can save you both time and money. A good hint is to keep your lathe inserts sharp. Because a sharp lathe insert makes cleaner cuts and lasts longer as a pencil does. Another tip: match the right insert to the right material—steel inserts in aluminum is gonna do nothing!

Consider the material you are working with, hard or soft, when selecting the proper lathe insert for your job. Will you need smooth edges or rough cuts? By answering these questions, you select the right lathe insert for the workpiece.