Desirable Materials: CNMG Face Mill[4]. It is used for very precise cutting of materials such as metal, plastic, or wood. In this lesson, we will cover more info on the CNMG face mill, its machining process and applications. It is travel CNMG face mills.

A CNMG face mill is a type of cutting tool used for shaping and cutting materials. It is a special design, which removes the material from the piece we are working on. In industries like automobiles, aircraft, and production, CNMG face mills are used.

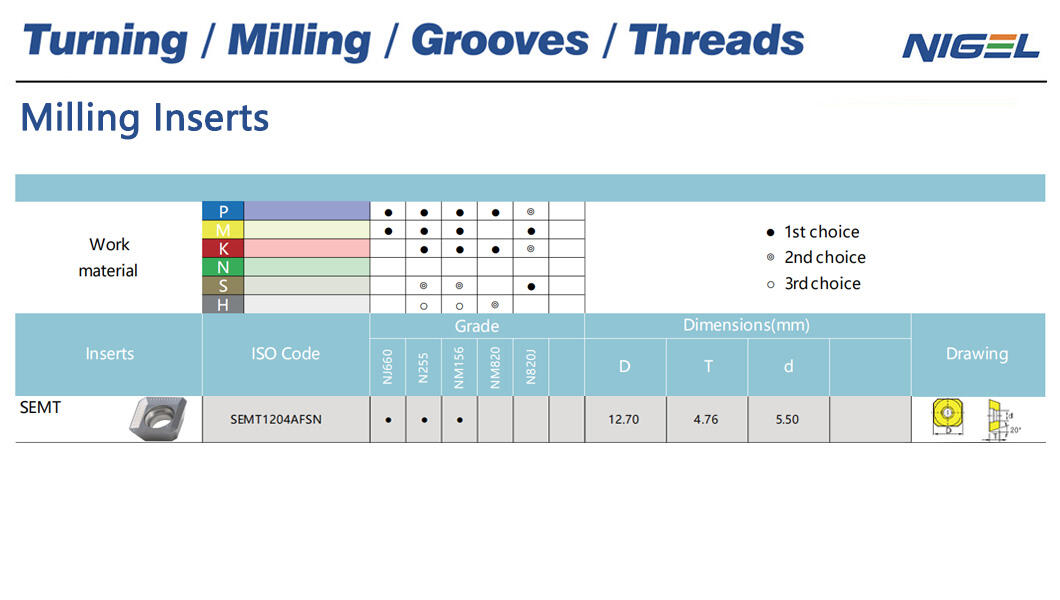

Getting the most from a CNMG face mill requires selecting the proper parameters. That includes things like how fast the tool spins, how deep the cut is, and how quickly the tool moves. Selecting the right type of inserts for the CNMG face mill is also crucial. Inserts vary, and getting the proper one will assist the instrument perform higher.

This is because there are several advantages to using a CNMG face mill, especially for precision work. The tool is designed to provide accurate and consistent results. And this means it is excellent for things that must be very precise. Companies can also save money thanks to saving time and increasing productivity, the CNMG face mill also helps in at this level.

Most CNMG face mills use inserts of one type or another, and each has its own unique characteristics. There are inserts for rough cutting, and there are others for finishing. Selecting the right insert to do the job goes a long way in promoting tool longevity and effective performance. There are various kinds of inserts including carbide, ceramic, and coated inserts.

The decision for proper settings to allow for a successful use of a CNMG face mill is very critical. Using different settings impacts how the tool engages with the material, which alters the quality of the final work. If you are selecting settings, you have to consider the material, the type of insert, and the way you want your surface to appear. Other than some trial and error with the settings, checking the results, there's no hard, fast route to finding what works best for a CNMG face mill.