Introduction:

Milling inserts are essential components used in milling operations across various industries, offering numerous benefits that enhance performance, efficiency, and cost-effectiveness.

High Precision and Accuracy:

Milling inserts provide precise and repeatable cutting action, ensuring high-quality surface finishes and adherence to tight tolerances.

Dimensional Accuracy:

They allow for high dimensional accuracy, which is crucial for producing parts with exact specifications.

Exceptional Surface Finish:

These inserts can achieve smooth and fine surface finishes, reducing the need for additional finishing operations.

High Material Removal Rate:

Milling inserts are designed to efficiently remove large amounts of material, significantly speeding up the milling process.

Quick Tool Changes:

Indexable inserts can be quickly and easily replaced, reducing downtime and improving overall productivity.

Versatility:

Milling inserts can be used to machine a variety of materials, including steel, stainless steel, cast iron, aluminum, titanium, and non-ferrous metals.

Multiple Applications:

They are suitable for various milling operations, such as face milling, edge milling, slotting, profiling, and contouring.

Heat Resistance:

Designed to withstand high temperatures, these inserts maintain performance even in demanding milling conditions.

Improved Chip Control:

The geometry of milling inserts is optimized to improve chip formation and evacuation, enhancing machining efficiency and preventing damage to the workpiece or tool.

Efficient Chip Removal:

Effective chip control leads to a more stable machining process and better surface finish.

Interchangeable Inserts:

Inserts can be easily swapped out for different shapes, sizes, and materials depending on the specific milling operation.

| Inserts ISO Code | Grade | Dimensions(mm) |

|

SPMT120408-D51

|

N255 | D: 12.70 / T: 4.76 / d: 5.50 |

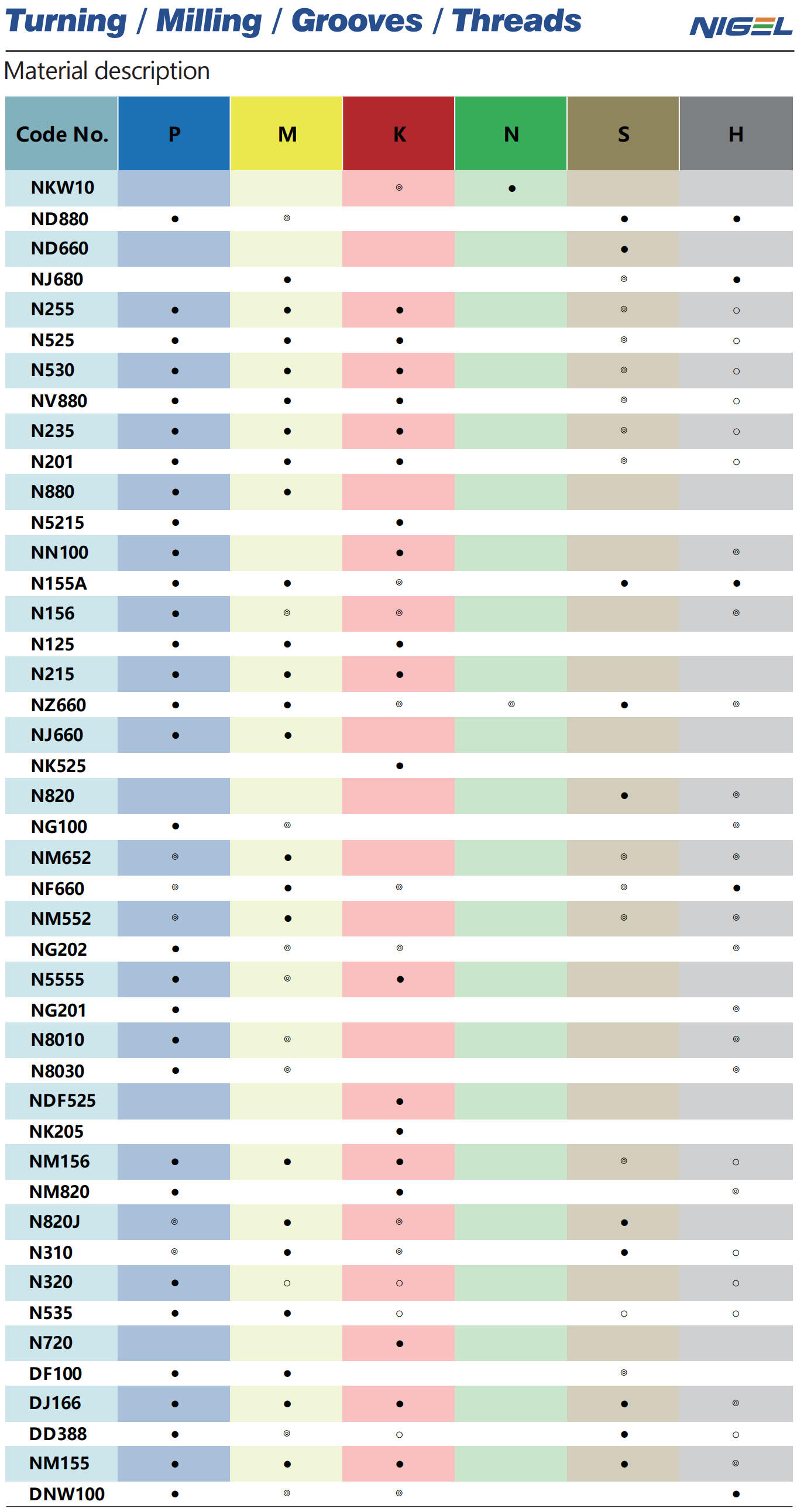

Grade Reference: