Choosing The Right Milling Insert For A Better Surface Finish

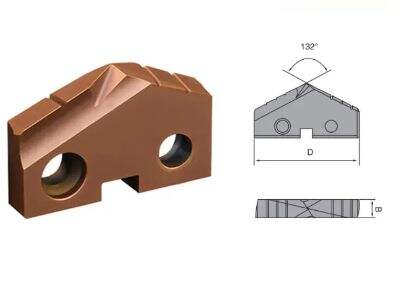

Full Story How to Choose the Right Milling Insert for Your Operations When it comes to maximizing the surface finish of your milling operations, the key is to select the ideal milling insert. Milling inserts are essential tool points that directly determine the quality of the surfaces that you are able to produce within your machines. You can greatly improve the surface finish of your workpiece by choosing the proper inserts that are ideal for your cutting requirements.

Tips for a Smooth, Consistent Surface Using Milling Inserts

Here are some tips to ensure smooth and consistent surfaces with milling inserts. start by ensuring you’re using the right insert geometry for the material you’re cutting. The best results are with the metal inserts having different geometries, depending on the material. Also make sure your inserts are always sharp and in good shape. Dull and worn inserts are going to effect negatively your workpieces surface finish. Finally adjust cutting data speed, feed and depths of cut to maximize your milling insert success.

The Advantages of Using High-Quality Inserts

Good quality milling inserts have several advantages that can help you to maximize the surface finish of the components you machine. These inserts are meant for better cutting action resulting in a smoother and more uniform surface. Furthermore, premium-quality inserts ensure an extended service life resulting in higher productivity by minimizing the frequency of tool replacement. By using premium inserts, you can achieve greater precision and higher accuracy in your milling work, resulting in finer surface finishes on your machined workpieces.

Surface Finish Improvement by Means of Precision Machining Processes

Fine machining techniques are indispensable for improving the surface finish by using high quality milling inserts. Through methods such as high speed machining, trochoidal milling, and the right choice of toolpath, you can achieve better finishes and accuracy while also hitting the desired tolerances. Advanced machining capabilities like CNC control and tool monitoring systems can improve the performance of your milling Inserts, delivering greater quality surface finishes to your machined parts.

High-Quality Inserts and Their Use in Milling

It is necessary to use high quality inserts for milling to get a good surface finished as well as performance in machining. These inserts are engineered specifically to be able to handle high cutting forces and temperatures, providing stable and reliable processes. High quality inserts, when combined with advanced coatings and geometries, can deliver great chip control and excellent tool life in the production of superior surface finishes in many materials. With a NIGEL system and top quality inserts, the surface of your milling work becomes top class, smooth and even to serve up to the most demanding craftsmanship.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

AZ

AZ

BN

BN