Gear cutting tools are crucial when it comes to precise work. The tool you use can make a difference in how your end product comes out. That’s why choosing the right one is so crucial. But how can you tell which will be the best for the task at hand? How to Select the Appropriate Gear Cutting Tool for Your Precision Machining.

Importance of proper selection of gear cutting tool is explained as follows:

The correct choice of gear cutting tool is a key factor in whether to the success of whole project. You would hate yourself if you used the wrong tool and then got a piece that doesn’t fit together correctly or isn’t doing what it’s supposed to. That’s why it’s essential to spend time choosing the best gear cutting tool for the job.

What to consider in selecting a gear cutting tool for precision machining:

When selecting a gear cutting tool there are the following points to consider. One of the key elements is the type of material you’re working with. But, clearly, some materials are more difficult to cut than others, so you’re going to need a tool that’s up to that challenge. Consideration for size and shape of the gear you are cutting should also be another point. You’ll also need a tool that can make the right size and shape without any errors.

INTRODUCTION TO DIFFERENT TYPES OF GEAR CUTTING TOOLS:

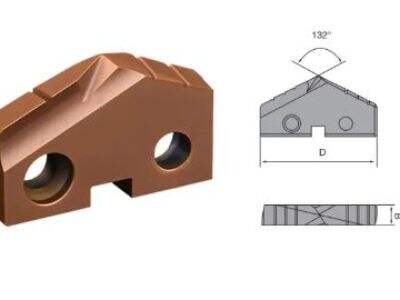

Translation There are various types of gear cutting tools available. Some of the more popular ones are gear hobs, gear shaper cutters and gear milling cutters. There are strengths and weaknesses to each type of tool, so it’s crucial to choose the best one for your project. Gear hobs for cutting teeth on gears, while gear shaper cutters are used to shape the internal teeth of gears. Application Gear Milling cutters can be applied and operate as, but are not limited to, the following: Types of gears Gear type Gear specification мы Technology Training the formation of joining experience.

Best Practices for Increased Performance and Efficiency from Your Gear Cutting Tools

When you’ve selected the proper gear cutting tool, you will want to ensure that you are using it properly. Here are a few suggestions to help you get the most from your gear cutting tool, performance and efficiency-wise:

-Ensure that your tool is sharp and in good working order before beginning any cutting. And a dull tool can result in errors and uneven cuts.

You're not using the proper speed and feed rate for your material. To slice too fast or too slow can give you trouble with your gear.

Make sure to apply proper cutting fluid to keep your bit cool, lubricated and to prevent dulling.

Then cut WELL and and TAKE YOUR TIME. Speeding through the sequence can result in mistakes.

The role of the correct cutter in the quality and accuracy of the machine as a whole:

Your choice of gear cutting tool will make a big difference in the overall quality and accuracy of your job. Choose the wrong tool and you could have a piece of work that doesn't perform as intended, or doesn't fit when pushed together. But if you take the time to consider and select the proper tool for the job, you can make sure that your project turns out exactly as you want it to.

It is therefore essential to select the correct gear cutting tool for precision machining to achieve outstanding results. Knowing the significance of using the right tool, weighing the variables involved, and learning about the types of tools available, optimizing performance and efficiency, and understanding the effect a suitable tool has on the quality and accuracy of your machining, you can ensure your projects are finished just right. So whether its the Fine gears on a watch or the Coarse gears of a diesel engine its important you select the correct gear cutting tool for the task at hand from NIGEL.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

AZ

AZ

BN

BN