Karbid Plastinalı Uçan Kəsici Alətlər səthi hamarlaşdırıb parlaqlıq verə bilən xüsusi alətlərdir. Uçan kəsiciyə dişli təkər Karbid Kesim Aləti qoymaq hər şeyi təxminən düzəldər və daha sürətli olar! Düzgün karbid platinanın seçilməsi və düzgün quraşdırılması onların effektiv şəkildə tələb olunan funksiyasını yerinə yetirməsini təmin etmək üçün vacibdir. İndi isə karbid plastinalı uçan kəsici alətlərdən ən yaxşı nəticəni necə əldə edəcəyinizi nəzərdən keçirək!

Karbid dəyişdirilən fly cutterlar xamı hamar edən sirli çubuqlardır. Səthlərlə işləyərkən narahat edici qabarıqları və şişkinlikləri aradan qaldırmaq üçün sərt karbid kənarları ilə təchiz olunmuşdur. Karbid dəyişdirilən fly cutterla onu fırladarkən, sadəcə onu çox sürətlə çevirib bütün səthin parlaq görünməsini təmin edirsiniz. Müxtəlif formaları və ölçüləri var ki, müxtəlif tapşırıqlara uyğun gəlir və kəsmə və formalandırma dünyasında çox universal alətlərdir.

Karbid plastinalarla uçan kəsilmənin bir çox üstünlüyü var. Karbid son dərəcə sərt aşınmaya davamlıdır və bərk səthlərdə istifadə edilsə belə uzun müddət dayana bilər. Karbid plastinalardan istifadə edərək materialı tez bir şəkildə kəsə bilərsiniz və bu zaman kənarlar çox tez aşınmadan hamar qalır. Bu, işinizi daha asan və səmərəli hala gətirərək az vaxtda daha çoxunu etməyinizə imkan verir. Karbid plastinalar həmçinin hər dəfə peşəkar görünüşlü, dəqiq və təmiz kəsilmiş kənarlar almağınıza kömək edir.

Fly rezini üçün uyğun karbid plastinaların seçilməməsi pis nəticələr verə bilər. Siz kəsdiyiniz materialın növünü, işin həcmini və işi nə qədər tez yerinə yetirmək istədiyinizi nəzərə almalısınız. Müxtəlif karbid plastinalar müxtəlif formalı və bucaqlı olaraq hazırlanmışdır və müxtəlif materiallarda ən yaxşı performansı göstərir. Düzgün platinanı seçdikdən sonra onu düzgün şəkildə quraşdırmaq lazımdır. Kəsdikdə platinanın düşməməsi üçün onu kəsiciyə SİXCA bərkidin. (bunun necə işlədiyinə buradan baxın) Gördüyünüz iş üçün platinanı doğru istiqamətdə yerləşdirmək üçün təlimatlara diqqətlə əməl etməlisiniz.

Karbid dəstəli flycutter-inizi maksimum potensialdan istifadə etmək üçün səmərəli və dəqiq işləməlisiniz. Bu, aləti — və ya səthi — zədələmədən materialları tez və təmiz kəsmək üçün doğru sürət və təzyiq tətbiq etməyi nəzərdə tutur. Həmçinin, kəsiciyə öz kəsici qüvvəsini və dəqiqliyini saxlatmaq üçün təmiz və itkin saxlanılması vacibdir. Əgər ona yaxşı qayğı göstərər, müntəzəm təmir-baxım apararsanız və düzgün şəkildə istifadə edərsinizsə, bir kəsici illər boyu sizə xidmət edər.

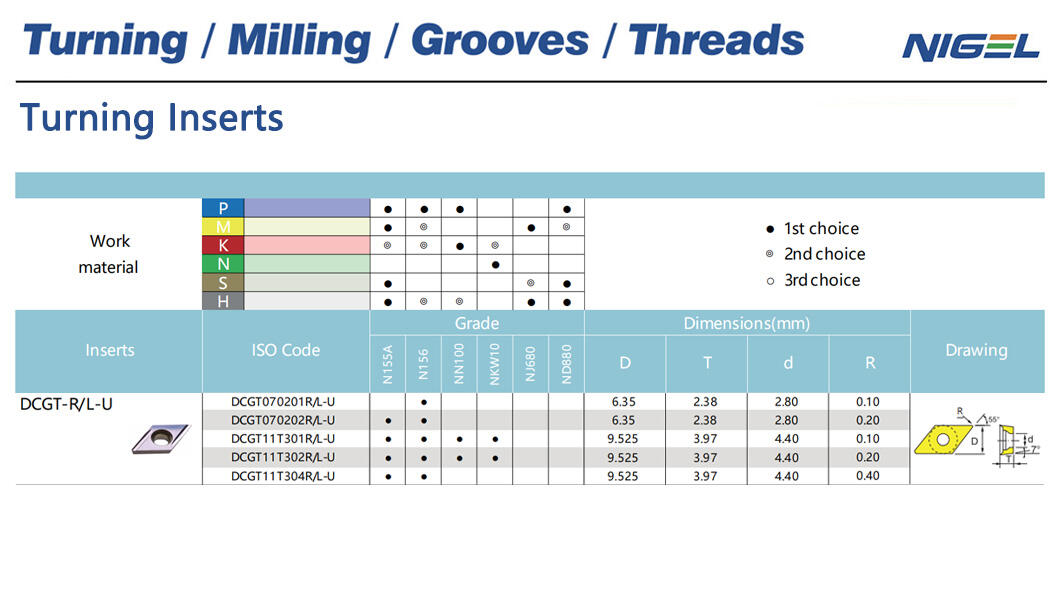

Növləri – Fly cutter-larda istifadə oluna bilən 3 əsas karbid dəstə növü var. Onlar müxtəlif karbid nümayişlərinin müxtəlif xüsusiyyətlərinə görə fərqlənirlər.

Uzaqdan kəsmə üçün istifadə olunan karbid plastinaların bir çox növləri var və bu plastinalar işin növünə və emal olunan materiala görə təşkil edilir. Bəzi plastina növlərində metal kimi sərt materialları kəsmək üçün daha iti kənarlar nəzərdə tutulur, yumşaq materiallar üçün isə ağac daxil olmaqla hamar kənarlar tətbiq olunur. Ən yaxşı nəticəni əldə etmək üçün kəsici alətlə uyğun gələn platinanı seçin: üz frezalar (geniş dibli və dairəvi platinaya malik kəsici) sizə gözəl, təmiz kəsik verəcək. İstifadə edə biləcəyiniz müxtəlif karbid platinanın növlərini bilmək, kəsici ehtiyaclarınız üçün ən yaxşısını seçməyinizə kömək edəcək.