Vnmg 330 tool inserts is the place to be in metal cutting. Such tools are used in CNC machining in order to efficiently cut metal and in this article, we are going to take a look at the basics of Vnmg 330 inserts, explore the possible applications in metal cutting and find out how it can help the metal cutting process to be more efficient. We’ll also give you some tips on how to get the best out of Vnmg 330 inserts and discuss ways they can be utilized in CNC turning applications.

Vnmg 330 insert is a cutting tool that is used in a CNC machine for cutting metal. They are constructed of hard material such as carbide that can withstand the heat of metal cutting. The “330” in Vnmg 330 tells you about the size and shape of the insert, and the design of the insert tells you how it cuts the metal. These inserts are disposable and intended to be replaced when dull or worn, so you can keep on cutting without stoppage.

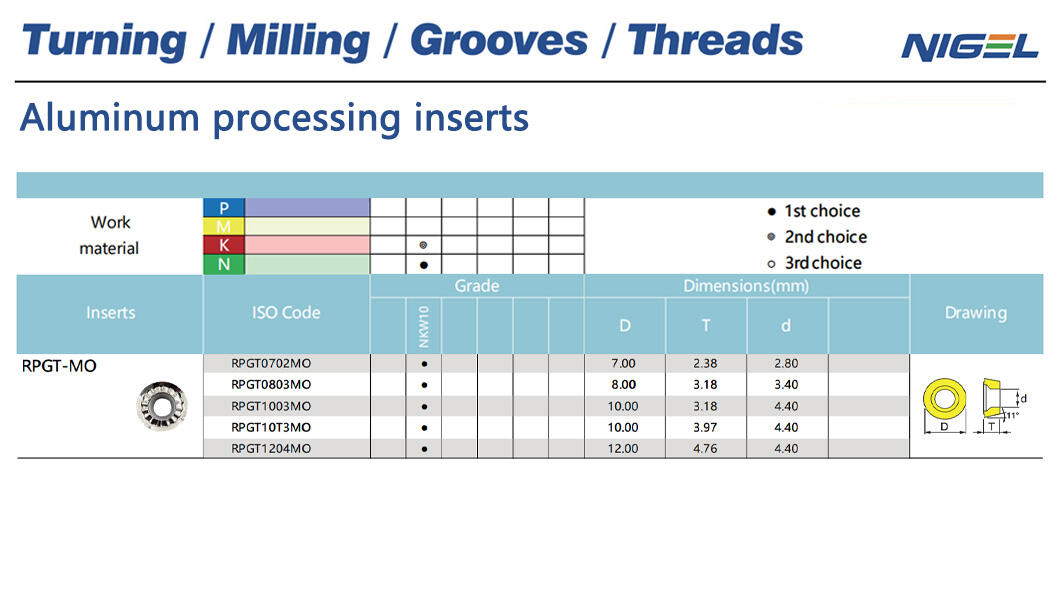

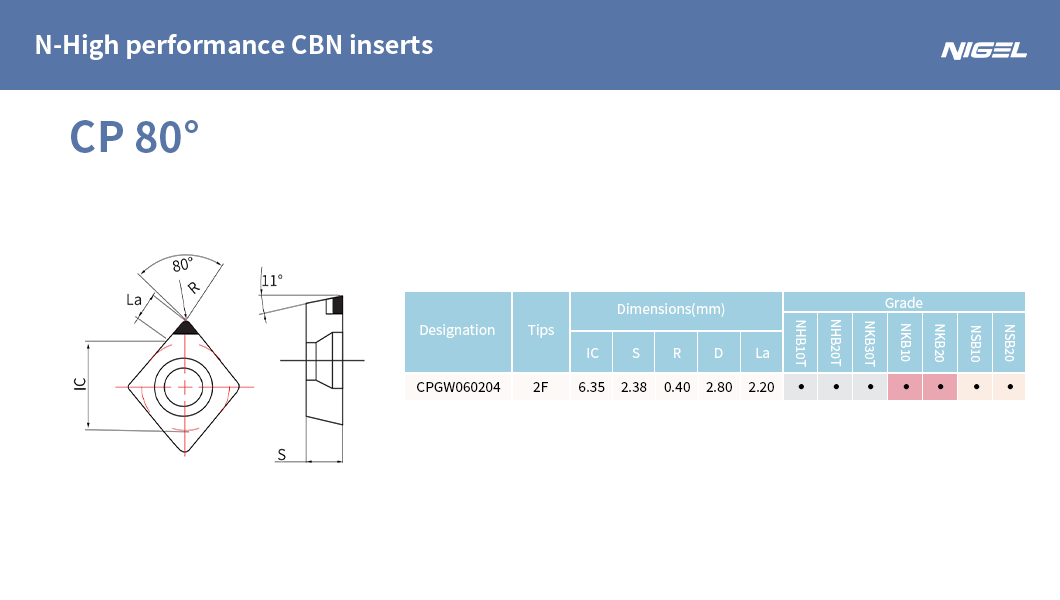

Vnmg 330 inserts work for turning, milling and drilling. These inserts are able to cut various metals such as: steel, aluminum and titanium. They are suitable for cutting solid tubes and hollow tubes, which means they are the perfect tool to use in a wide-range of machining applications. Vnmg 330 inserts can help add fine surface finishes, eliminating the need for grinding or other finishing operations.

Key Features Case use of Vnmg 330 inserts can enhance productivity and efficiency in CNC machining. These cutting inserts can help reduce machining time and eliminate the energy that is spent on each machining job. With Vnmg 330 insert, the machinist can run the tool at higher cutting speeds and feed rates for faster production and lower cost. What's more is that Vnmg 330 turning inserts are built to last longer tool lives, keeping you up and running for a longer period of time.

There are some key tips and tricks to ensure that you are getting great performance from your Vnmg 330 inserts. First, be sure that the insert is fixed securely in the holder Carbide Gear Hobs Cutting Tool itself to eliminate vibration and erratic cutting. Second, modify the cutting parameters (speed and feed rates) of the cutting operation to the particular metal being cut. Third, regularly check the insert to see if it is worn or damaged, and replace it if necessary in order to maintain cutting precision. Finally, coolant or lubricant helps to eliminate heat and friction on the cut, enhancing the life of the insert and improving machining performance.

Here are a couple of the benefits of using Vnmg 330 inserts for CNC machining: First, such inserts can be used in a variety of metal cutting operations, with fewer tools needed. Second, high cutting speeds and accuracy are introduced by Vnmg 330 inserts enabling accurate and efficient machining. Third, Vnmg 330 inserts have a long service life, reducing your cost of maintenance over time. Say what you willOverall, a Vnmg 330 insert is a must have featuring in metal cutting tasks.