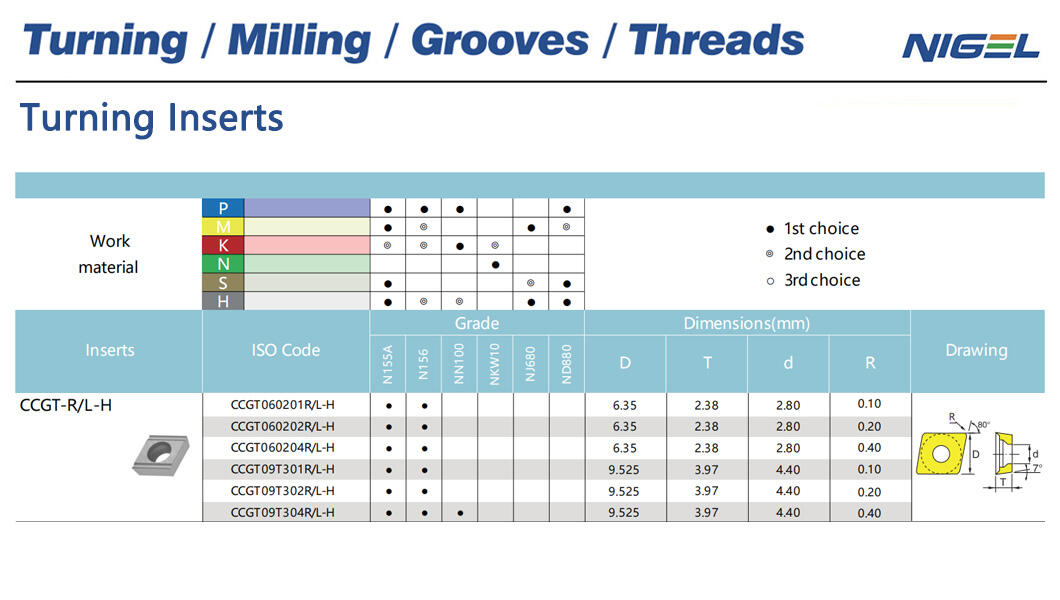

Picking the ideal turning inserts is essential when machining titanium. A turning insert is a tool for lathes for the turning of titanium and similar tools. Titanium is a hard tough metal, require turning inserts of best quality that can easily withstand while cutting.

Titanium alloys is created by blending titanium and other metals. These fixtures are found in facilities such as aircraft and medical instruments. When working with titanium alloys, opt for turning inserts designed specifically for the material. Such inserts are coated with special coatings and designed with shapes that allow them to be able to cut titanium alloys without wearing out quickly.

Tips to make your turning inserts last longer when processing titanium. Seek out inserts that are made of durable materials such as carbide or ceramic, as these will have a longer life. Second, examine the coating on the inserts; coatings such as titanium nitride can reduce friction and heat when cutting down. Finally, chooses the inserts with the proper shape of cutting edge for titanium, they will help them cut better.

When machining titanium, one of the most important factors is using quality turning inserts. It can be tricky to cut this metal. If you keep using inferior quality inserts, they corrode quickly causing poor surfaces and at the same time more expenditure. With NIGEL turning inserts, you can achieve better performance, faster cutting, and save money on the way by investing in quality inserts.

Well one of the big issues in cutting titanium is it generates a lot of heat. That heat can bake the tools inside the machine and make cutting more difficult. To address this, high-temperature turning inserts should be used. new inserts utilize special coatings and materials that have heat-resistant properties, which help to lower heat, result in cleaner cutting, and in turn longer tool life. Using the correct hammer and anvil can also help to reduce heat in titanium machining.