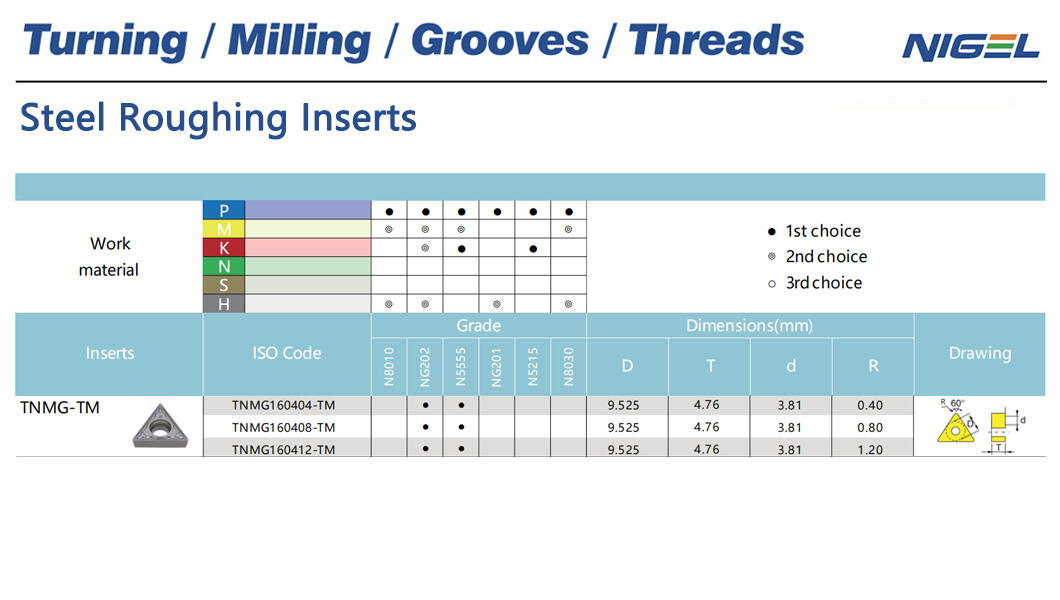

The TNMG 432 carbide inserts are also specially designed for effective and faster metal turning. They are composed of a durable material known as carbide, which allows them to easily slice through metal. This text will provide an overview of TNMG 432 inserts, their benefits, how to utilize them effectively, their operation in machines, and how they stack up against other tools.

They are small square-shaped inserts used by machines like lathes to cut metal. It is used to remove substance from some work and to shape it in a proper way. These inserts vary in the amount of cutting edges and their shapes, but the TNMG 432 is one of the most common for turning metal.

Benefits of Using TNMG 432 Carbide Inserts First of all, they are extremely durable and long-lasting. This allows them to operate at great speeds and slice through hard metal without feedback. With them lasting longer, you don’t need to change them regularly, which not only saves you time but also contributes to doing the work faster.

Second—and this is where they are REALLY useful—these inserts control the formation of those metal pieces that break away from the main body. One area that requires some guidance is chip control during CNC machining. Inserts with TNMG 432 —they can get the same high-performance life workers expect with consistent results.

Second, inspect the insert regularly for signs of wear or damage, such as chips or dullness. Rapidly exchange worn inserts so cut quality remains high and workpiece damage is minimized. Watch out for the state of the insert, workers can help ensure TNMG 432 inserts last longer.

As you evaluate TNMG 432 inserts against other carbide inserts when cutting and shaping metal, here is what you should consider. TNMG 432 inserts are classified as versatile; they can be used to machine a variety of materials. For this reason they are a popular choice for many turning jobs. Besides, their strength and chip control add to their uniqueness among tools.

Other types of carbide inserts can feature surface treatments and coatings designed for specific applications and materials. Good as they are, in some situations, TNMG 432 inserts are a pragmatic and economical choice for general turning. Ultimately, whether TNMG 432 is your best choice or not is based on the job requirements.