Nigel Precision Machinery Co., Ltd." to be the mark with respect to which all of her other dealings, if any, in such desk equipment are measured. Specialized in precision machining, our company offers over 20 sets of CNC tools that serve to improve the efficiency and quality of production. PCBN and PCD inserts, carbide products and drills - Nigel is dedicated to providing machinists with the best quality global cutting tools. In our state-of-the-art production facility, every stage of both the R&D and manufacturing processes comply with a stringent quality control system to guarantee uncompromising quality.

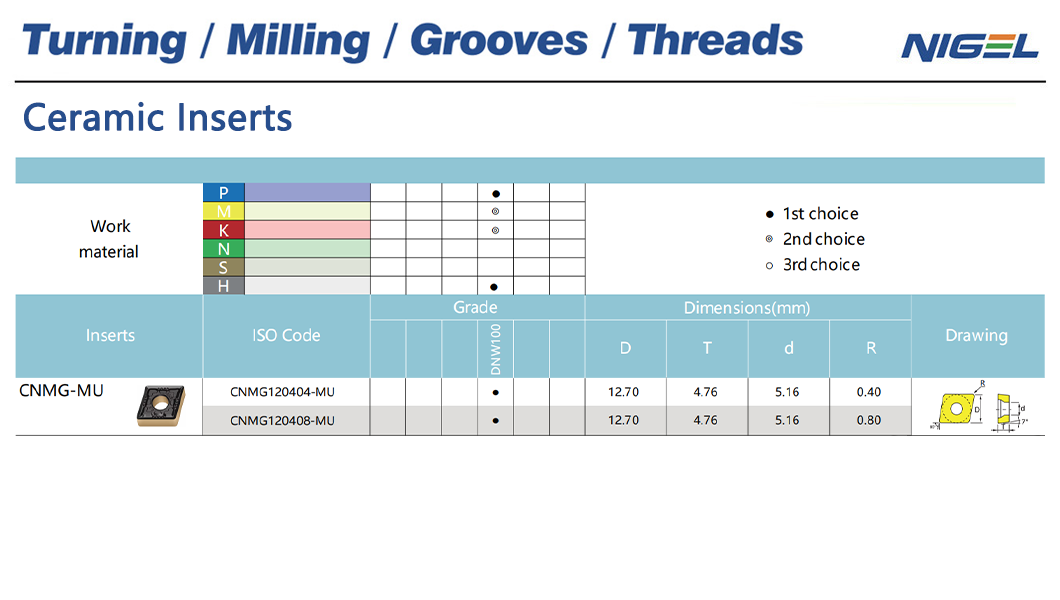

Carbide Gear Hobs Cutting Tool CNMG 644 inserts are an essential equipment for any machinist who wants to increase his throughput. These inserts have been developed for high_velocity machining at the highest feed rates and provide industry leading performance with low tool wear. Featuring state of the art Chipbreaker technology, along with geometries that are specifically designed for high performance facing, CNMG 644 Inserts provide top-notch effectiveness on various materials such as steel and stainless. Using CNMG 644 Inserts, machinists are able to utilize increased cutting speeds which results in lower cost per part and improved surface finishes - translating into enhanced overall productivity.

We offer high-quality CNMG 644 inserts at competitive prices, and Nigel Precision Machinery Co., Ltd. knows what high standards you expect from our products, so we set them! Our wide variety of cutters are available to help you optimize your machining processes with CNMG 644 inserts that have been developed with a hands-on approach, for quality and accuracy. Nigel believes in exceptional quality and customer service – that’s why every insert he creates is held to the highest standards of performance and longevity. So, as a small outfit or massive company - Nigel provides you with great value services to help keep your production running smooth without breaking the bank.

HSS Gear Hobs Cutting Tool CNMG 644 inserts is a breakthrough for machinists who demand precision machining results. With a rigid substrate and special cutting edge design, the inserts of this family are ideal for a broad range of parting/grooving applications from roughing to finishing. Featuring superior chip control and wear resistance, CNMG 644 inserts are ideal for high-speed, high-feed machining, ensuring reliable performance and long tool life. CNMG 644 inserts will keep machinists in high productivity requirement cutting, delivering the highest quality and cost effectiveness on all any cut.

Nigel Precision Machinery Co., Ltd Provides CNMG 644 inserts for turning and achieving precision machining. Featuring coatings and geometries designed to work with a variety of materials, Seco’s range of insert grades and styles deliver excellent performance in all types of cutting processes, uniting the highest accuracy with maximum reliability. Working with ferrous and non-ferrous material, the CNMG 644 inserts from Nigel are the perfect way to improve your machining capabilities; give you tighter tolerances, smoother surface finish, and an overall better tool life. Leave it to Nigel to arm you with what you need in order to move your precision machining one step further.

These inserts are for high speed and feed turning to provide excellent chip control, wear resistance, cutting performance & extended tool life improving production yields.

CNMG 644 turning inserts feature state-of-the-art chip-breaking technology, well-designed cutting geometries, and long-term durability, making them a favorite among machinists who demand performance and consistency in their machining operations.