In terms of machining, Gear Cutting Tools are particularly important to precision and efficiency in a variety of fields. Nigel Precision Cutting Tools Co., Ltd. is top manufacturer of cutting tools and product with rich experiences, provides top-quality low cost productivity performance grooving CNC inserts to our customers from all over the world. This inserts are an integral part of grooving products such as metal, plastics and composites to offer superior performance making material removal more accurate, quick and cost effective.

There are lot of advantages that come with the use of CNC grooving inserts to industries who want to refine their machining process. One major benefit is in its versatility, as it can be used to apply on multiple materials and applications. Whether cutting out of aluminum, stainless steel, or titanium; CNC grooving inserts bring consistency and accuracy to every cut. Furthermore, these inserts also provide for a decrease in tool wear and the life of the tool so that there is generated no delay and reduction in overall cost to businesses. “Nigel’s CNC grooving inserts can make a light cut, producing better finishing with tighter tolerance and ensuring that its user has high productivity, high efficiency and quality machining.”

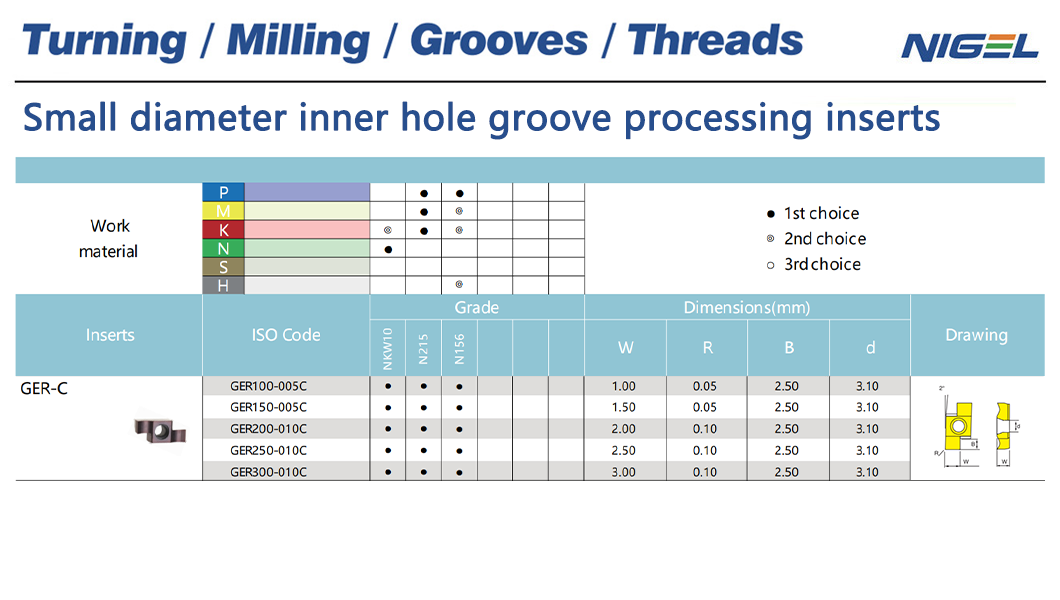

Choosing the correct CNC grooving insert is key for getting the best performance and effectiveness out of your machining applications. When selecting an insert, however, factors such as material type, cutting speed(s), cutting depth(s) and feed rate should be considered. Nigel’s technical team can help to choose the right insert geometry, coating and cutting edge design for the particular application. If you need inserts for internal grooving, external grooving or threading, Nigel has a solution to meet your precision machining needs.

Nigel Precision Machinery Co., Ltd. is the most reliable place to buy premium CNC grooving inserts with competitive prices. Committed to accuracy and meeting your needs, Nigel has affordable machining services. Nigel offers both high performance and economy grooving inserts for your brand machines, small shop or large manufacturer! Browse our product offering and see why past customers have let us design the next generation of inserts to help make new levels of productivity possible.

CNC grooving inserts are famous for the efficiency and precision..parseFloat(users may however encounter some common problems in their use) One such challenge is the chip formation issue which may give rise to poor surface finish and tool breakage. To solve the problem, cutting parameters such as cutting speed and feedrate should be adjusted towards optimal chip control. Further by examining the insert for wear and correct seating this can help avoid problems of tool deflection and vibration. Click here to read full article Techniques for Maintaining and Troubleshooting CNC Inserts Users of CNC grooving inserts can enhance their life and performance by employing good maintenance practice.