Carbide scraper inserts are useful to have around and may help your metalworking projects run more smoothly. Applications Precision cutting – These carbide inserts are great for precise cutting tasks which makes your job easier and precise., in this post, we’re going to explain how to sharpen carbide scraper inserts, advantages of using them in the metalworking process, installing and replacing them used in the process, various applications, & how to select the perfect carbide scraper insert for your project requirements.

In order to maintain your carbide scraper inserts for precision cutting, it is necessary to regularly sharpen them. When feet become dull, re-sharpening can be done with a sharpening stone or diamond file. Just take the stone or file to the edge of the insert at that angle, and let it slide along the edge to sharpen it, keeping the pressure light. Remember to grind both sides of the insert evenly to maintain the correct edge angle.

There are a number of advantages to using carbide scraper inserts for the metalworking in general. For one, they are very strong so can take the heat and pressure of heavy-duty cutting jobs. In addition, carbide insert cuts are precise and never leave ridges, burns or other undesirable marks on your material. They also last longer than the stock steel inserts, saving you time and money in the long run.

Carbide Scraper Inserts replacement and installation with just a few easy steps. First, remove the old insert by loosening the bolt that holds it in place on the tool. Then clean the tool holder completely from chips and dirt. Next, place the new carbide scraper insert inside the holder and secure it with the wrench. Align the insert before use to maintain perfect cutting! Thanks to these actions, you are able to install or replace carbide scraper inserts within your equipment in a fast and simple manner.

Make no mistake, carbide inserts are handy tools to have around, not only for metalworking, but for woodworking too. They are popular in woodworking, plastics, and automotive shops. Their ruggedness and precise cutting make them perfect for fine detail cuts in a wide range of materials. Whether cutting wood, plastic or metal, a carbide scraper insert can give you the power you need to get the job done right.

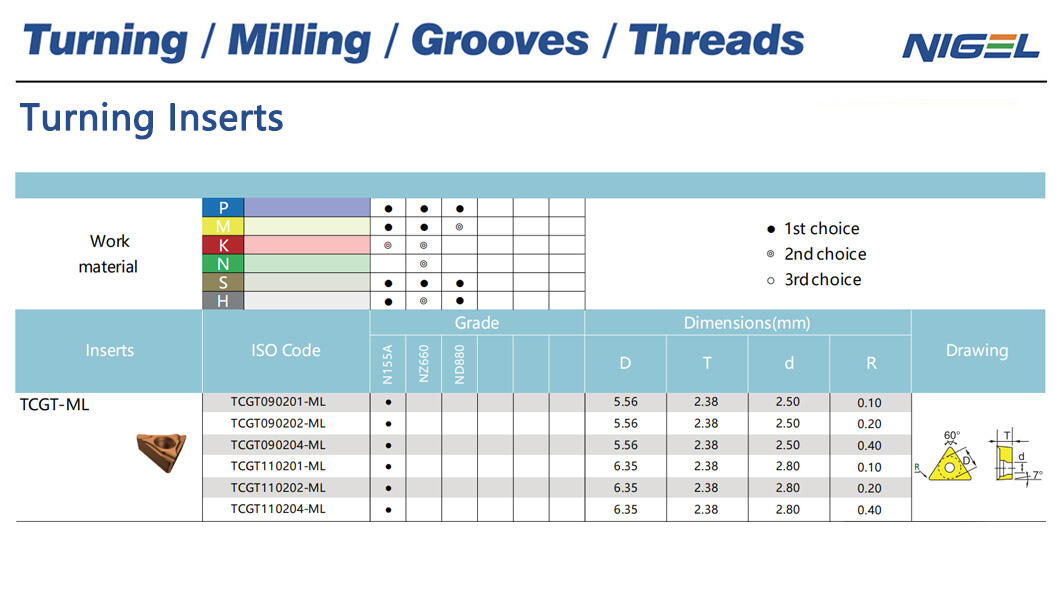

Choose the appropriate carbide scraper insert for your application by taking into account the material you will work with, the type of cutting you will be doing, and the appropriate size of the insert. The inserts vary according to the material to be cut and the cutting process employed, so select the one best suited to your specific needs. Also verify the dimensions and compatibility of the insert with your tools to confirm that it will fit. With a proper carbide scraper insert, you can get exceptional cutting performance and top-notch results in your projects.