Introduction:

Threading inserts, essential tools in machining operations, offer numerous advantages that significantly enhance the efficiency, precision, and overall productivity of threading tasks.

High Precision and Accuracy:

Threading inserts produce threads with high accuracy, ensuring uniformity and adherence to specifications across multiple parts.

Excellent Surface Finish:

These inserts are designed to produce smooth, high-quality threads, reducing the need for additional finishing operations.

High Cutting Speeds:

Threading inserts allow for high cutting speeds, which can dramatically reduce cycle times and increase productivity.

Multiple Threads per Pass:

Modern threading inserts can often cut multiple threads in a single pass, further enhancing efficiency.

Versatility:

Threading inserts can be used for a variety of materials, including carbon steel, stainless steel, cast iron, aluminum, brass, copper, and certain plastics.

Various Thread Types:

They can create different types of threads, such as internal and external threads, and different thread forms (e.g., metric, UNC, UNF, BSPT, NPT).

Durability:

Made from high-quality materials and often coated with advanced materials like titanium nitride (TiN) or titanium aluminum nitride (TiAlN), threading inserts are highly durable.

Heat and Wear Resistance:

These inserts can withstand the stresses and high temperatures generated during the threading process, extending their operational life.

| Inserts ISO Code | Grade | Dimensions(mm) |

| 30N/E 1.00ISO | NM155 | L: 30.00 / H: 16.00 / T: 5.50 |

| 30N/E 1.50ISO | NM155 | L: 30.00 / H: 16.00 / T: 5.50 |

| 30N/E 2.00ISO | NM155 | L: 30.00 / H: 16.00 / T: 5.50 |

| 30N/E 2.50ISO | NM155 | L: 30.00 / H: 16.00 / T: 5.50 |

| 30N/E 3.00ISO | NM155 | L: 30.00 / H: 16.00 / T: 5.50 |

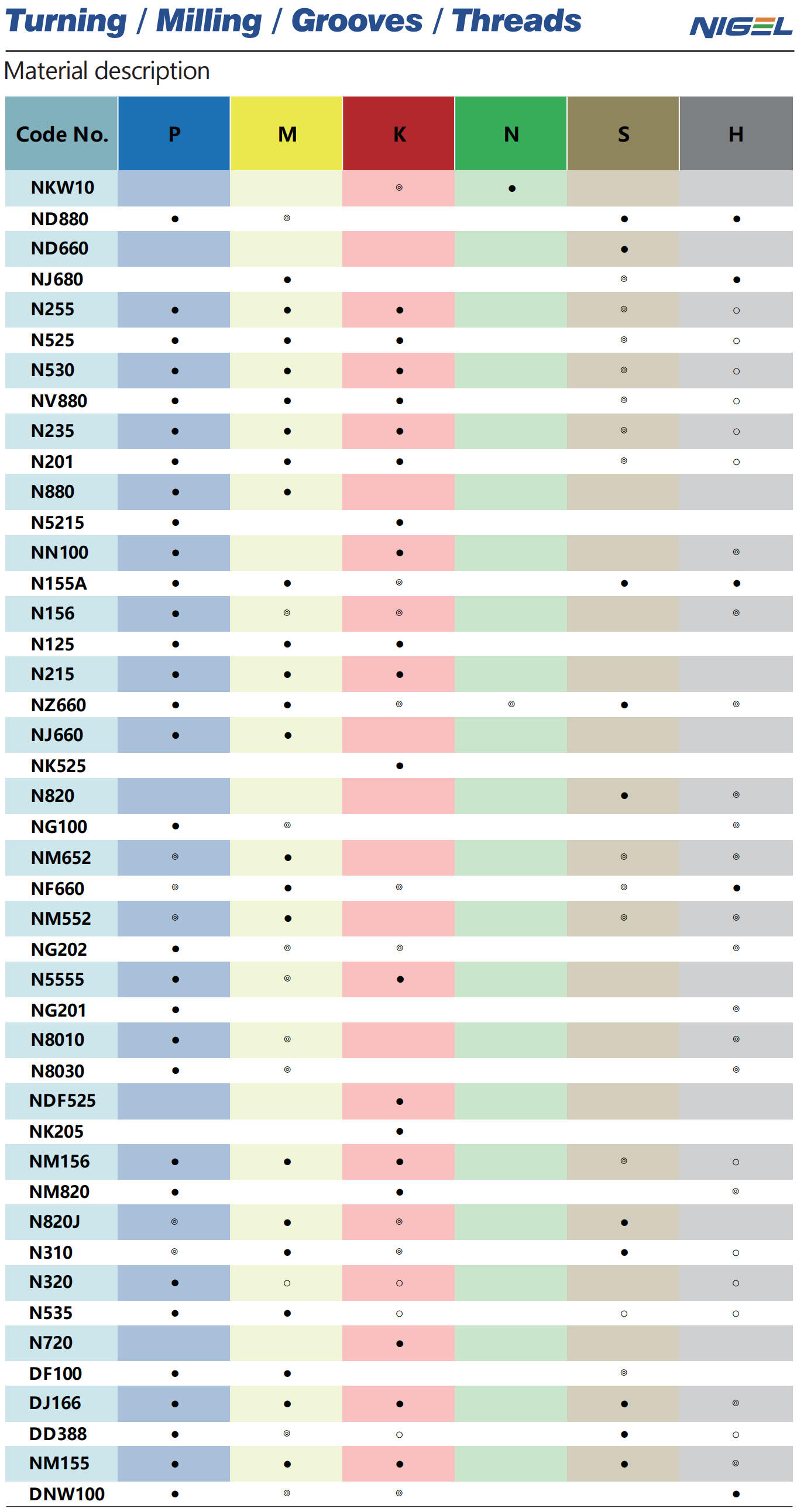

Grade Reference: